Yixing Technology specializes in automotive sheet metal stamping, automotive sheet metal fabrication, and other advanced metalworking services, offering customized solutions for the automotive industry. With expertise in car sheet metal fabrication and custom auto sheet metal fabrication, we provide high-precision sheet metal fabrication for automotive components. Our services include automotive sheet metal fabrication through processes such as stamping, stretching, welding, and laser cutting, ensuring the highest standards of quality, durability, and efficiency for critical automotive parts like door frames, battery packs, and energy storage enclosures.

As the automotive industry evolves, especially with the rise of new energy vehicles, Yixing Technology’s commitment to advanced automotive sheet metal fabrication allows us to meet the increasingly complex demands for both traditional and electric vehicle components. With rigorous certifications and a focus on precision, we are your trusted partner in the manufacturing of high-performance automotive parts.

Our state of the art equipment, professional skills and strict quality standard TS16949 can ensure the sheet metal parts we produce meet the customers' design and even exceed their expectation. We use materials as thin as 0.003" with internal feature tolerances within ±0.001".

As a professional sheet metal fabrication factory, we design and make the precision molds and dies in house which can meet the strict quality requirement of the design and also reduce the turnaround time. Small modification of the molds can be done very quickly in house.

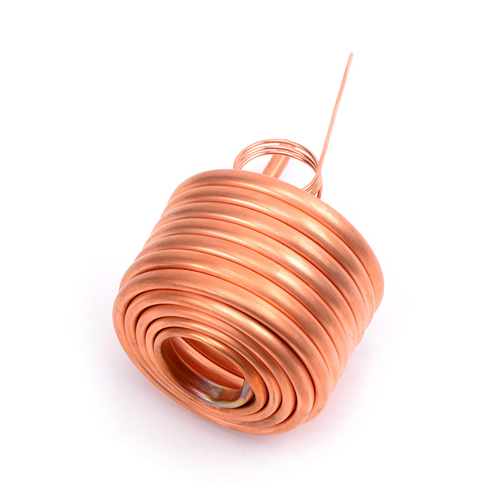

Automobile industry has high demand on the sheet metal material. We are very serious in the selection of the material and we make sure the fabrication material is per the drawing and do strict inspection on chemical composition and mechanical performance testing. We can handle cold rolled steel, hot rolled steel, SECC, SGCC, copper, aluminum, stainless steel, titanium, and other special materials if customers require.

Strength and Stiffness: Automotive sheet metal parts must offer sufficient strength and stiffness to endure the forces and vibrations experienced during vehicle operation. Our sheet metal fabrication automotive services ensure that materials like carbon steel, alloy steel, and stainless steel are precisely formed to meet these requirements for structural integrity.

Corrosion Resistance: Corrosion resistance is crucial for extending the lifespan of auto sheet metal fabrication components. We recommend materials such as aluminum alloys (like aluminum magnesium alloy and aluminum manganese alloy) that provide exceptional resistance to environmental factors, ensuring long-term durability, especially in automotive body panels and energy-efficient components.

Ease of Processing: For efficient automotive sheet metal fabrication, the chosen material must be easy to process through methods like stamping, deep drawing, welding, and laser cutting. We offer advanced automotive sheet metal stamping and car sheet metal fabrication services, enabling precise and cost-effective fabrication of complex parts like doors, hoods, and battery enclosures.

Repairability: In cases of damage or wear, repairability is key. We select materials that facilitate easy repair or replacement, ensuring your automotive sheet metal components remain functional and cost-effective throughout their lifecycle.

At Yixing Technology, we uphold the highest standards of quality control throughout our automotive sheet metal fabrication processes to ensure that every part meets the rigorous demands of the automotive industry. Our expertise in automotive sheet metal stamping, car sheet metal fabrication, and custom auto sheet metal fabrication guarantees precision, durability, and performance in every component we produce.

Disassembly and Assembly: We prioritize the convenience of disassembly and assembly in our auto sheet metal fabrication processes. This ensures that the components are easy to maintain, replace, and service, contributing to the long-term efficiency and performance of the vehicle.

Technical Difficulty: Our team carefully considers the shape, curvature, and structural characteristics of each sheet metal part during the manufacturing process. Using advanced techniques in automotive sheet metal stamping and sheet metal fabrication automotive, we ensure that every component meets the exact design specifications and functional requirements.

Surface Treatment: After automotive sheet metal fabrication, we apply comprehensive surface treatments such as spraying, chrome plating, and electrophoretic painting. These treatments enhance both the aesthetic appeal and the corrosion resistance of the parts, ensuring durability and a premium finish for all vehicle components.

Dimensional Accuracy: We rigorously control the size and shape of each sheet metal part during the manufacturing process to achieve precise dimensional accuracy. This guarantees a perfect fit for each component and ensures the overall quality and appearance of the vehicle, from body panels to intricate parts.

Welding and Connection: The manufacturing of car sheet metal fabrication components involves precise welding and connection techniques, including spot welding, riveting, and bolting. These processes are essential to ensure the structural integrity, strength, and sealing of every part.

Shaping and Leveling: Our sheet metal fabrication automotive processes include advanced shaping and leveling techniques to ensure that every part is perfectly flat, with a high-quality finish. This step is crucial for achieving the desired appearance and ensuring that the parts meet the functional requirements of the vehicle.

Part Consistency: Consistency is key in custom auto sheet metal fabrication. We maintain strict quality control to ensure that all produced parts have uniform dimensions and consistent quality, ensuring compatibility and seamless integration during the final vehicle assembly.