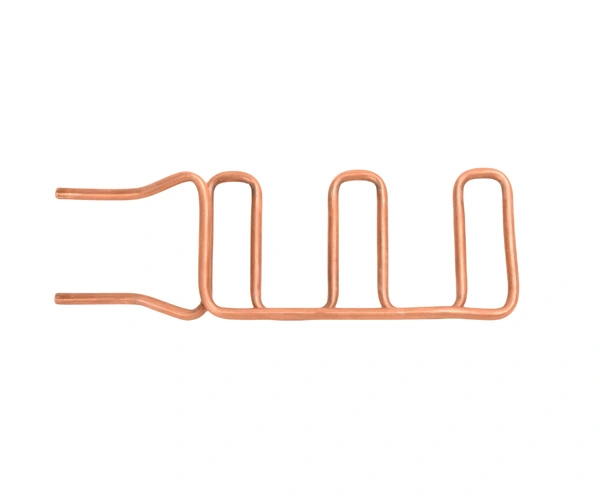

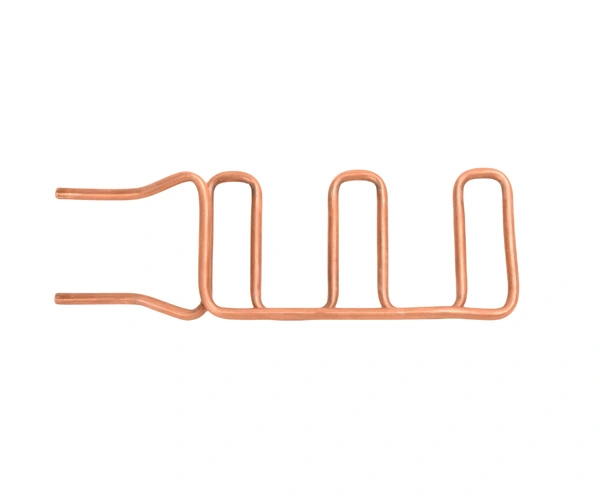

Material: Bronze

Surface: mill finish

Customized Size

Tolerance: ±0.005 inch

Ⅰ. The bending method of copper pipes

Copper pipes can be bent using the following two methods:

1. Conventional bending

Conventional bending is a method of bending copper pipes along a certain curve using a mold. According to the diameter of the copper pipe and the required angle, manual bending or machine assisted bending methods can be used. The specific steps are as follows:

a. Making a mold: Make a suitable mold according to the required angle and bending radius.

b. Prepare copper tube: Flatten both ends of the copper tube and apply grease or lubricant to a certain area.

c. Start bending: Place the copper tube into the mold, apply force to fit the copper tube against the mold, and smoothly bend it towards the mold until the desired angle is reached.

2. Temporary bending

Temporary bending refers to the local bending of copper pipes along a certain curve by hand, without the need for frequent bending. The method of temporary bending is relatively simple, and the following are the specific steps:

a. Preparation tool: Prepare a large pliers and insert the jaws into the desired bend of the copper tube.

b. Tapping the copper tube: Use a copper hammer to slowly tap the copper tube along the locking pliers until it is bent to the desired angle.

Ⅱ. Factors and precautions affecting the bending of copper pipes

1. Copper pipe diameter: The smaller the diameter of the copper pipe being bent, the less force is required and the easier it is to bend.

2. Copper tube thickness: The thinner the copper tube is bent, the better its flexibility, and the easier it is to bend.

3. Smooth inner wall: The higher the smoothness of the inner wall of the copper tube, the more uniform the bending position, and the better the bending.

4. Lubricant: When bending copper pipes, applying lubricant can reduce the friction of the copper pipes, reduce scratches, and make the bending of the copper pipes smoother.

5. Precautions: During the bending process, the surface of the copper pipe is prone to scratches or deformation, so it is necessary to protect the surface of the copper pipe when bending; In addition, different specifications of copper pipes require different bending molds, otherwise it may cause deformation or damage to the copper pipes.