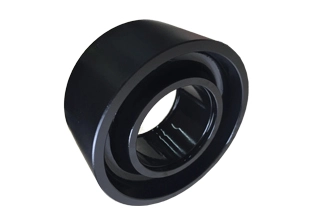

Black oxidation treatment from Yixing Technology is a common method of chemical surface treatment. The principle this metal surfact treatment is to create an oxide film on the metal surface to isolate the air and achieve rust prevention. When the appearance requirements are not high, blackening treatment can be used. The blackening treatment on the surface of steel parts is also called bluing. Yixing Technology's Black oxidation treatment is a surface coating method commonly used on military knives because it can eliminate reflections.

Fasteners, hardware, and tools are often treated with black oxide because it provides a matte, aesthetically pleasing finish that is corrosion-resistant, durable, and easy to grip.

Automotive and aerospace components such as engine components, suspension systems, and landing gear are often treated with black oxide for corrosion-resistance and wear-resistance effect.

Industrial equipment such as pumps, valves, and machinery are often treated with black oxide for corrosion- and wear-resistant surfaces.

Black oxidation treatment differs from other popular finishes in several ways.

Aesthetics: If you don't have special color requirement, black oxide treatment is a good choice as it can only be black color. Anodizing, electroplating and powder coating can provide various colors options.

Durable: Black oxide treatment provides a more durable, corrosion-resistant surface that is generally more resistant to wear and tear than other finishes.

Cost: To create a black oxidation treatment finish is relatively simple, time-fast and cost-effective compared to other finishes such as electroplating or anodizing.

Environmental protection: Different from phosphating, black oxidation treatment has no pollution to the environment and no need for exhaust facilities.