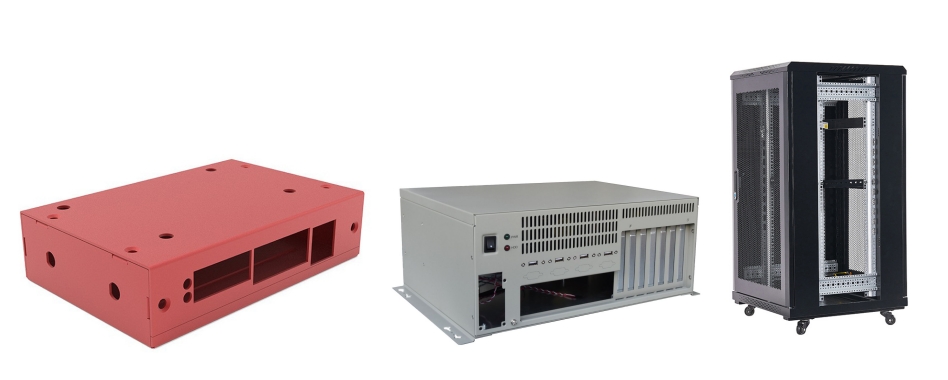

Precision sheet metal fabrication plays a very important role in the telecommunication equipment industry, especially in the manufacturing process of key components such as metal enclosure, metal box, metal chassis, metal casings and metal brackets. These precision sheet metal components must fit together precisely to ensure stable operation of the equipment over a long period of time. Precision sheet metal fabrication can ensure the high accuracy, thereby ensuring stable and excellent performance of telecommunication equipment. Yixing Technology is a leading sheet metal box fabricator for telecommunication.

Sheet metal box in telecommunication industry must meet high quality and technical standards. Achieving this standard requires the use of high-quality materials and the use of advanced technology and processing equipment. Precision sheet metal fabrication technology is the key to meeting these requirements, ensuring sheet metal box meets high standards and can effectively compete in the market.

Selecting the right material for custom sheet metal box is crucial for ensuring durability, functionality, and cost-effectiveness. The choice of material depends on the application, environmental conditions, mechanical requirements, and budget. Below are some common materials used for custom sheet metal box, along with their properties and typical applications:

Mild Steel (Low Carbon Steel): High strength and durability. Good machinability and weldability. Prone to rust and corrosion if not treated.

Stainless Steel: Excellent corrosion resistance. High strength and durability. Aesthetic appeal with a polished or brushed finish. More expensive than mild steel.

Aluminum: Lightweight and corrosion-resistant. Good thermal and electrical conductivity. Easily machinable and weldable. Lower strength compared to steel.

Galvanized Steel: Zinc-coated for improved corrosion resistance. Durable and cost-effective. Heavier than aluminum.

Copper: Excellent electrical and thermal conductivity. Corrosion-resistant and antimicrobial. Expensive and heavy.

Brass: Good corrosion resistance. Aesthetic appeal with a gold-like finish. Lower strength compared to steel.

The surface finish for custom sheet metal box is critical for enhancing durability, improving aesthetics, and providing protection against environmental factors such as corrosion, wear, and chemical exposure. The choice of surface finish depends on the material, application, and desired appearance. Below are common surface finishes for custom sheet metal box:

Powder Coating: A dry powder is applied electrostatically and then cured under heat to form a hard, durable layer. It provides Excellent durability and resistance for sheet metal boxes.

Anodizing (for Aluminum): An electrochemical process that creates a protective oxide layer on the surface of aluminum. It enhances corrosion resistance and surface hardness and also provides a decorative finish with various color options for sheet metal box.

Painting: Liquid paint is applied to the surface, either by spraying, brushing, or dipping. It provides basic corrosion protection for sheet metal box in a wide range of colors and finishes(e.g., matte, gloss).

Plating: A thin layer of metal (e.g., chrome, nickel, zinc) is deposited on the surface through electroplating or electroless plating. It provides a decorative, corrosion resistance shiny finish for sheet metal box.

Galvanizing: A zinc coating is applied to steel or iron to protect against rust. It creates excellent corrosion resistance, especially for outdoor used sheet metal box.

Brushing or Polishing: Mechanical processes that create a smooth, reflective, or textured surface.

It enhances aesthetic appeal for sheet metal box.

We choose high-quality raw materials and refuse to cut corners. We can provide mill factory certificates and third-party testing reports for raw materials. Ensure production according to customer drawings and materials.

As an experienced precision sheet metal fabrication factory, our engineers will design internal production processes based on customer drawings, provide production process flow charts, inspection plans, control plans, and other documents to ensure orderly production of products.

Products in the telecommunications industry generally use processes such as laser cutting, sheet metal bending, stamping, and welding. We are equipped with relevant equipment to ensure the quality and delivery time of our products.

Sheet metal box are the most commonly used products in the telecommunication industry. The following is the general production process of the custom sheet metal box:

The production of sheet metal box requires the use of some metal materials, such as steel plates, aluminum alloys, magnesium alloys, etc. Before production, these materials need to be classified, cleaned, and dried to ensure that their quality meets production requirements. At the same time, it is also necessary to inspect and maintain the molds required for the sheet metal box to ensure the service life and production efficiency of the molds.

In the production of sheet metal box, steel plate is one of the most commonly used materials. In the plate cutting process, the raw materials need to be cut into plates of appropriate size first, which is the basis for subsequent production links. According to the design drawings of the sheet metal box, the steel plate is cut into the required shape and size using fabrication methods such as laser cutting, shearing or sawing.

Blanking is an important link in the sheet metal box production process. After the sheet is cut, the sheet is blanked with the help of the blanking machine. It should be noted here that the error range and size need to be strictly controlled during the blanking process to ensure the smooth progress of subsequent processing links.

In the bending process, the panels of the sheet metal box are bent by the bending machine or bending die. The bending angles and errors must be strictly controlled to ensure the accuracy and quality of the sheet metal box.

In the assembly process of the sheet metal box, the plates are drilled, the fixings are arranged neatly, and the assembly is carried out according to the drawings and requirements. This includes fixing the upper and lower sides, left and right sides, installing distribution panels, installing brackets, and finally cleaning and inspecting the assembled sheet metal box.

Quality inspection is a very important link in sheet metal box production. After the sheet metal box production is completed, each sheet metal box needs to be inspected and inspected to ensure that their quality meets the requirements and meets the required standards. During this process, the appearance of the sheet metal box also needs to be inspected to ensure that there are no obvious scratches, deformations and other defects.

The above is a detailed explanation of the sheet metal box production process. Only by strictly following these procedures and accurately controlling the operation of each link can we ensure the production of high-quality, high-precision, and high-reliability sheet metal boxes.