Material: Q235 Q345

Surface: Polishing/Sandblasted/Anodized/Chrome Plating/Nickle Plating/Zinc Plating/Silver plating/ Heat Treatment etc

Customized Size

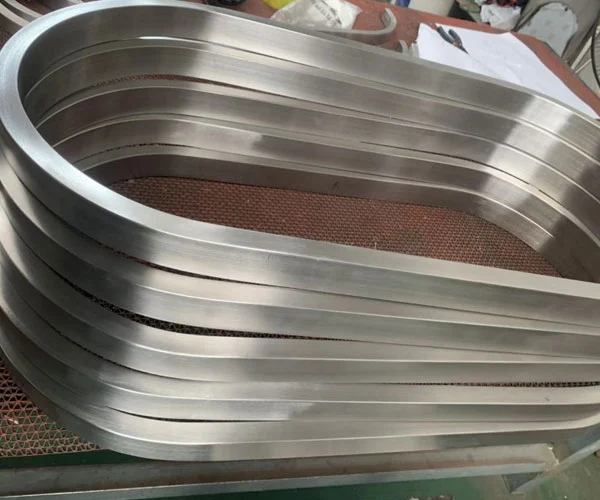

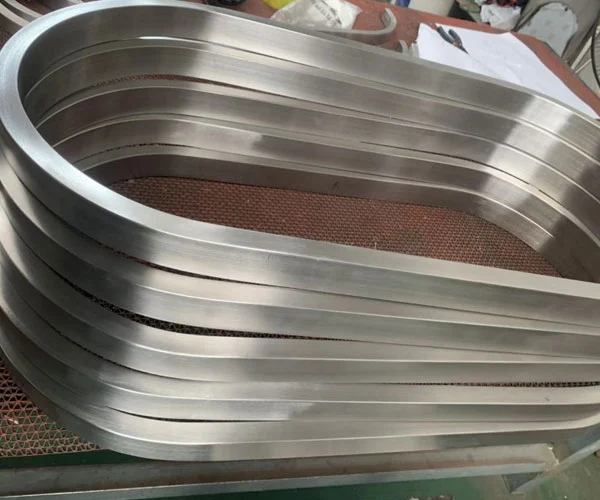

Tube bending and welding, stainless steel tube bending, profile bending

A. Manual bending method

1. Tool preparation

Bending tools, manual hydraulic presses, cutting machines, square steel pipes, measuring tools, etc.

2. Bending steps

(1) Cut the square steel pipe according to the required length;

(2) Chamfer the cut square steel pipe to facilitate bending;

(3) Put the square steel pipe into the bending tool and adjust the required bending angle;

(4) Use a manual hydraulic press to apply pressure and bend the square steel pipe until it meets the required bending angle.

3. Tips

(1) Determine the bending angle and position to ensure that the bent square steel pipe meets the requirements;

(2) Choose a manual hydraulic press correctly and do not use unsuitable pressure tools;

(3) Bevel and cut carefully to prevent burrs or uneven cutting.

B. Mechanical bending method

1. Tool preparation

CNC pipe bending machines, square steel pipes, measuring tools, etc.

2. Bending steps

(1) Cut the square steel pipe according to the required length;

(2) Install the cut square steel pipe onto the CNC pipe bending machine and adjust it according to the required bending angle and radius;

(3) Use a CNC pipe bending machine to bend until the required bending angle is met.

3. Tips

(1) The CNC pipe bending machine needs regular maintenance to ensure the normal use of the equipment;

(2) Choose the correct CNC pipe bending machine and the appropriate square steel pipe bending mold;

(3) Pay attention to the strength and hardness of square steel pipes to avoid deformation or cracking.

In summary, according to different needs and process requirements, manual bending or mechanical bending can be chosen to bend the square steel pipe. Pay attention to the process specifications and precautions during use to ensure that the bent goods meet the requirements.