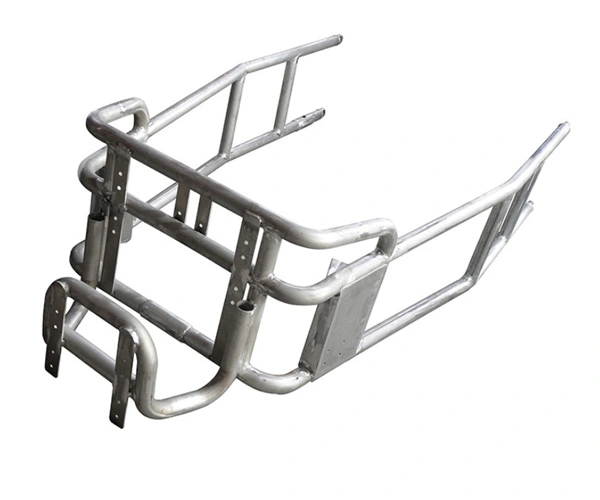

Material: aluminum

Surface: powder coating/painting etc available

Customized Size

Tolerance: ±0.02inch

Main Process: tube bending and welding

aluminum welding, equipment frame welding, bracket welding

CO2 welding, which uses CO2 with a purity greater than 99.98% as a shielding gas, is a melting electrode gas shielded welding process.

A mixed gas of 75-95% Ar+25-5% CO2 (standard ratio: 80% Ar+20% CO2) is used for gas shielded metal arc welding, which is called MAG welding.

① Use high-purity argon gas Ar299.99% as the protective gas for melting electrode gas protection welding of non-ferrous metals such as aluminum and aluminum alloys, copper and copper alloys;

② The process method of using 98% Ar+2% O2 or 95% Ar+5% CO2 as protective gas for melting electrode gas shielded welding of solid stainless steel welding wire is called MIG welding.

③ Melting electrode gas shielded welding using helium+argon inert gas mixture as protection.

Inert gas shielded arc welding, abbreviated as TIG welding, uses pure tungsten or activated tungsten (needle tungsten, bell tungsten, wrong tungsten, mace tungsten) as the non melting electrode.

The arc welding method of manually manipulating welding rods for welding.

A surface processing method that uses carbon rods as electrodes to generate an arc between the workpiece and the molten metal, and uses compressed air (pressure 0.5-0.7Mpa) to blow it away. Commonly used for welding seam root cleaning, beveling, repairing defects, etc.