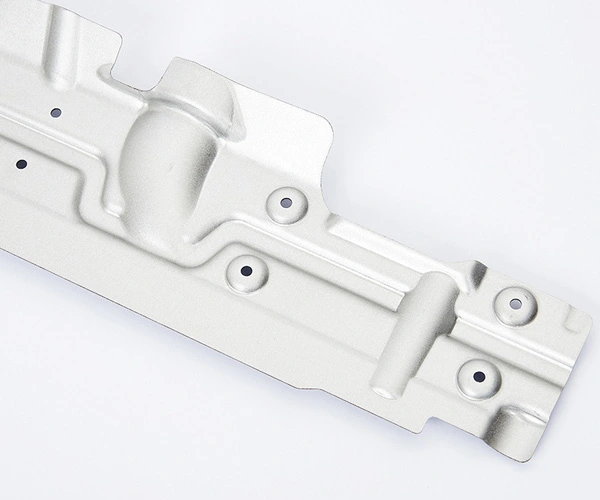

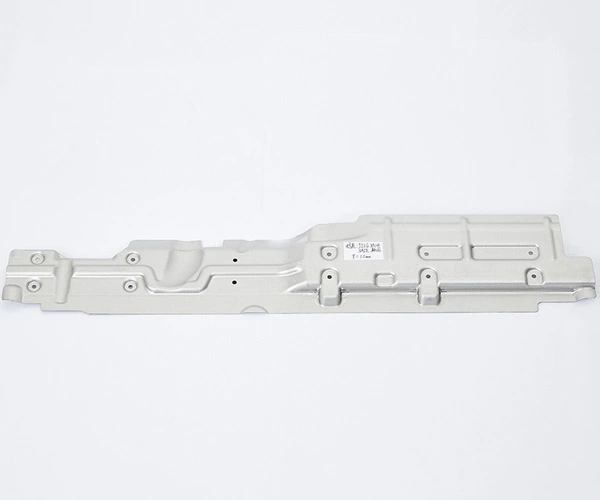

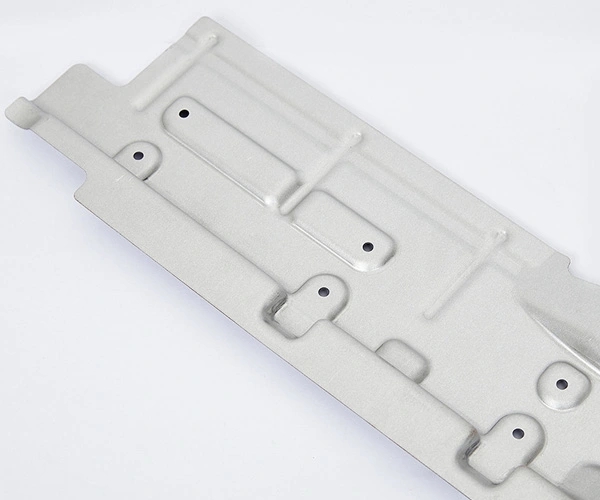

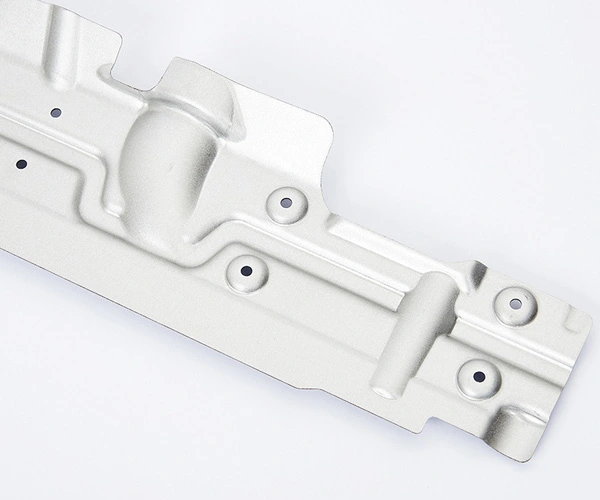

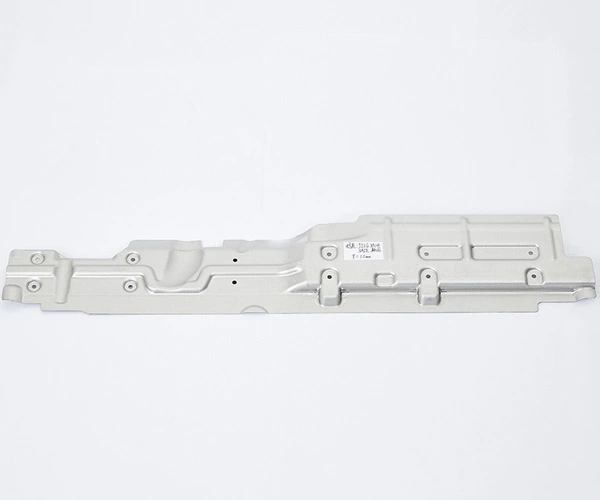

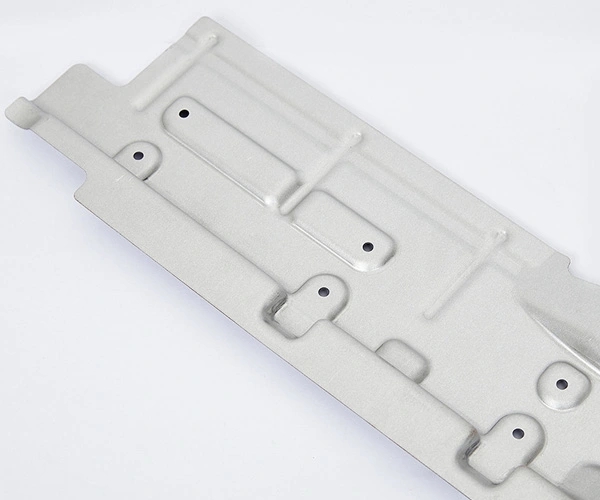

Mold Material: D2

Surface: Zinc plated/Painting

Customized Size

Tolerance: ±0.025mm

Automotive Metal Stamping, punching zinc plated car components, press irregular metal parts, china stamping factory, deep stamping

We work closely with the automotive industry to provide consistently accurate and dependable precision parts ranging in thicknesses from 0.005" to 0.5 "with a maximum part width of up to 48" . Our maximum press bed is capable of handling tooling of up to 240" by 70" with a maximum press stroke of 31".

These capabilities allow us to produce parts of virtually any size, including:

Heat Shields

Cylinder Head Gaskets

Radiator Frame Assemblies

Brake Components

Engine Components

Seating Components

BIW Components

Transmission Components

Brackets

Floor Panels

EV Battery Components

EV Charging Components

A-Frames

Battery Trays

The versatility of automotive metal Stamping enables manufacturers to craft parts in a range of materials, each with its unique properties and benefits.

Three of the most common materials in the stamping of automotive components are:

Aluminum

Carbon Steel

Stainless Steel

In addition to aluminum, carbon steel, and stainless steel, we utilize the following materials in our automotive metal stamping processes:

Titanium

Brass

Bronze

Copper

Inconel

Nickel Alloys

Yixing Technology has become one of the leading metal stamping, laser cutting, and metal fabrication companies in the industry. Our team of experts is well-versed in producing precision parts that meet stringent specifications, and we work closely with our customers to determine the ideal material and die-stamping process for their project’s unique needs.

To learn more about our metal stamping services, or to work with us on your next project, contact us today.