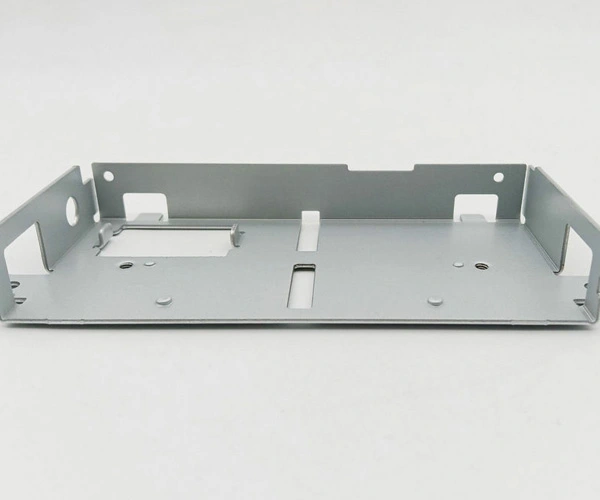

Material: Zinc aluminum plate /carbon steel /stainless steel /aluminum /copper /galvanized sheet available

Thickness: 0.8mm

Tolerance: ±0.1mm

Manufacturing process: sheet metal bending

Surface treatment: powder coating /painting /anodization /sandblasting /zinc coating etc available

Sheet metal bending, stamping, stainless steel bending, cabinet stamping

The bending radius of sheet metal is a required value in the sheet metal drawing, and it is difficult to determine its size in actual processing. In fact, the bending radius of a metal plate is related to the thickness of the material, the pressure of the bending machine, and the width of the groove under the bending die.

The relationship between the bending radius of sheet metal and the thickness of the sheet metal

1. Experience in sheet metal processing has shown that when the thickness of the sheet metal is not greater than 6 mm, the inner radius of the sheet metal bending can be directly determined by the thickness of the sheet metal.

2. When the plate thickness is greater than 6mm but less than 12mm, the bending radius of the plate is 1. 25 times to 1. 5 times the thickness of the board. When the plate thickness is not less than 12 mm, the bending radius inside the plate is generally 2-3 times the plate thickness.

3. When the bending radius R is 0.5, the average thickness of gold T is 0.5mm. If the radius size is greater than or less than the plate thickness, special mold processing is required.

4. When the metal plate needs to be bent 90 ° and the bending radius is particularly small, the metal should be planed first. It can also process the upper and lower molds of special bending machine molds.