Barrel plating, continuous plating, spot plating, and brush plating are common methods in electroplating processes, each with its unique characteristics and applications. Below are their differences and applications:

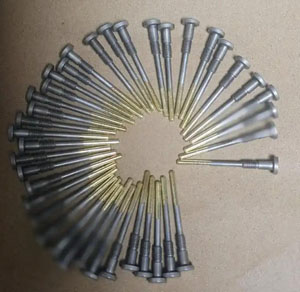

Definition: Barrel plating involves placing small parts into a rotating barrel, where the rotation ensures uniform contact with the plating solution, achieving electroplating. Post plating can use barrel plating, rack plating or other plating method.

Features:

Suitable for small, simply shaped parts (e.g., screws, nuts, washers).

High plating efficiency, ideal for mass production.

Relatively uniform plating layer, but may not fully cover complex shapes.

Applications:

Electronic components (e.g., connectors, terminals).

Hardware parts (e.g., screws, nuts).

Decorative plating (e.g., gold or silver plating).

Application in stamping parts and machined parts:

Stamping parts: small hardware parts (such as washers, springs).

Machined parts: small shaft parts, fasteners.

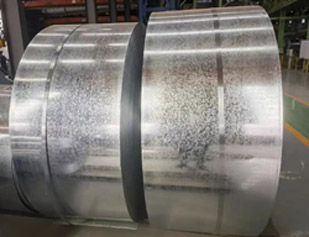

Definition: Continuous plating involves passing strip or wire materials (e.g., metal strips, wires) through an automated plating line for electroplating. The pre-plated raw material are usually used to further fabrication like laser cutting, stamping, welding etc. The surface treatment on these fabricated parts are called “pre-plated”.

Features:

Suitable for long strip or wire materials.

High production efficiency, ideal for large-scale continuous production.

Uniform plating thickness with stable quality.

Applications:

Electronics industry (e.g., copper foil plating on PCBs).

Metal wires (e.g., galvanized steel wires, tin-plated copper wires).

Application in stamping and machined parts:

Stamping: electroplating of coils or strips (such as galvanized steel strips, tinned copper strips). Machinery: electroplating of long bars or tubes.

Definition: Spot plating is a localized electroplating method where only specific areas of a workpiece are plated, while other areas are protected by masking or covering.

Features:

Suitable for workpieces requiring localized performance enhancement or repair.

Saves plating materials and reduces costs.

High flexibility, ideal for localized treatment of complex workpieces.

Applications:

Electronics industry (e.g., localized gold plating on circuit boards).

Repairing worn or damaged parts (e.g., shafts, gears).

Localized functional enhancement of precision parts (e.g., conductivity, wear resistance).

Packaging materials (e.g., tin-plated steel strips for food cans).

Application in stamping parts and machined parts:

Stamping parts: electroplating of local conductive areas (such as the contact points of connectors).

Machinery parts: local wear-resistant or anti-corrosion treatment (such as the tooth surface of gears, local areas of shafts).

Definition: Brush plating is a portable electroplating method that uses a brush or electrode with plating solution to directly plate localized areas on a workpiece.

Features:

Suitable for large or non-removable parts.

High flexibility, can be performed on-site.

Controllable plating thickness, ideal for repairs and localized enhancement.

Applications:

Repairing large mechanical parts (e.g., molds, shafts).

Localized functional enhancement (e.g., improving wear resistance, conductivity).

Localized plating of precision parts (e.g., aerospace components).

Application in stamping parts and machined parts:

Stamping parts: Local repair of large stamping dies.

Machined parts: Local repair or function enhancement of large shafts and gears.

Method | Suitable Objects | Features | Application Scenarios |

Barrel Plating | Small, simply shaped parts | High efficiency, mass production | Electronic components, hardware, decorative plating |

Continuous Plating | Strip or wire materials | Continuous production, high uniformity | PCB copper foil, metal wires, packaging materials |

Spot Plating | Localized areas | Material-saving, high flexibility | Localized gold plating on circuit boards, part repairs |

Brush Plating | Large or non-removable parts | Portable, on-site operation | Mechanical repairs, localized functional enhancement |

Roll plating: suitable for small, simple-shaped stampings and machined parts, especially for mass production.

Continuous plating: suitable for coil or strip stampings, as well as long-sized machined parts.

Spot plating: suitable for complex parts that require local functional enhancement or repair.

Brush plating: suitable for large parts or occasions that require on-site repair.

Each plating method has its unique advantages and suitable scenarios. Choosing the right method can improve production efficiency, reduce costs, and meet specific functional requirements.

Deeply rooted in custom metal fabrication in the past 20years, Yixing has used Barrel Plating, Continuous Plating, Spot Plating, and Brush Plating in our stamping parts, progressive stamped parts, cnc machined parts and weldments. With our expertise and rich experience, we can tailor per your specific requirement. Contact us today to see how we can help in your project!