At Yixing Technology, we provide cutting-edge electrophoresis painting services, ensuring superior electrophoretic paint application for enhanced durability, uniformity, and corrosion resistance. Our electrophoretic painting process caters to diverse metal materials processed through stamping, deep drawing, welding, and laser cutting.

With expertise in electrophoresis metal coating, we utilize both anodic and cathodic electrophoretic paints, delivering high-quality finishes tailored to specific project needs. This innovative process outperforms traditional spraying, offering consistent coating thickness and improved product longevity, making it an ideal solution for various industries.

1. Environmental Protection and Safety: By using water-soluble coatings and using water as the solvent, a large amount of organic solvents are saved, greatly reducing air pollution and environmental hazards, ensuring safety and hygiene, and avoiding the risk of fire hazards;

2. High Usage: High painting efficiency, low paint loss, and a paint utilization rate of 90% to 95%;

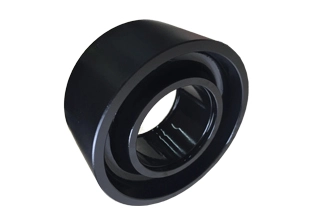

3. Uniform Coating Thickness and Strong Adhesion: The coating thickness is uniform, the adhesion is strong, and the coating quality is good. A uniform and smooth coating film can be obtained in various parts of the workpiece, such as the inner layer, depression, weld seam, etc., solving the problem of coating complex shaped workpieces with other coating methods;

4. High Production Efficiency: this type of surface treatment can achieve automated continuous production, greatly improving labor efficiency;

5. Big Upfront Investment: Yixing Technology's equipment is complex, the investment cost is high, and the power consumption is high. The temperature required for drying and solidification is high, and the management of coatings and coatings is complex. The construction conditions are strict, and wastewater treatment is required;

6. Color Limitation: Electrophoretic coating equipment from Yixing Technology is complex and highly technological, suitable for precise sheet metal fabrication production with fixed colors.

1. Automotive industry: Yixing Technology's electrophoretic paint is widely used in the automotive manufacturing industry, covering the painting of metal components such as car bodies, doors, and frames. It provides protection for cars in terms of corrosion resistance, durability, and aesthetic appearance.

2. Home appliance industry: Electrophoretic paint by Yixing Technology is widely used in the home appliance industry, such as the coating of products such as refrigerators, washing machines, air conditioners, and water heaters. It provides a durable coating that makes household appliances less susceptible to damage during use.

3. Construction and building materials industry: Electrophoretic paint can be used for the protection and decorative coating of building and building materials products such as metal doors and windows, railings, indoor and outdoor furniture. It can provide weather and corrosion resistance to adapt to various environmental and climatic conditions.

4. Electronic and communication equipment: Electrophoretic paint has applications in electronic and communication equipment, such as the outer shell of products such as mobile phones, computers, televisions, etc. It can provide insulation performance and decorative effects, while protecting the internal electronic components of the equipment.

5. Industrial equipment and machinery: Many industrial equipment and mechanical components require corrosion resistance and wear resistance, and electrophoretic paint has important applications in these fields.