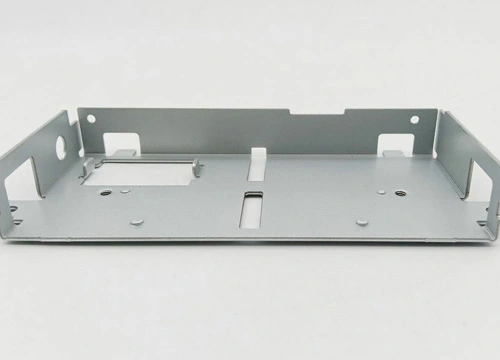

Printer Bracket Bending

Material: DC01+ Z275/carbon steel/stainless steel/aluminum/copper/galvanized sheet available

Thickness: 1.2mm

Tolerance: ISO 2768-m

Manufacturing process: sheet metal bending

Surface treatment: powder coating/painting/anodization/sandblasting/zinc coating etc available

Sheet metal bending, stamping, stainless steel bending, CNC bending

Sheet metal bending is a common process in sheet metal processing and one of the core technologies in sheet metal processing. It is achieved by bending and deforming metal sheets to meet the shape and angle requirements of the design. Mastering the sheet metal bending process is crucial for producing accurate sheet metal products. The basic knowledge of sheet metal bending includes the following aspects:

1. Material selection: The material used for sheet metal bending is generally metal sheets, commonly including cold-rolled sheets, hot-rolled sheets, stainless steel sheets, etc. Different materials have different mechanical properties, so suitable materials need to be selected according to design requirements before bending.

2. Bending process: Sheet metal bending can be completed by manual operation or mechanical equipment. Manual operation is suitable for small and simple parts, while mechanical equipment is suitable for large and complex parts. When bending, it is necessary to determine the position, angle, and radius of the bending according to design requirements, and use appropriate tools and equipment for operation.

3. Bending angle: Bending angle refers to the angle change of a metal sheet during the bending process. The size of the bending angle is determined according to the product design requirements, usually below 90 degrees. The larger the bending angle, the higher the requirements for material deformation and stress concentration.

4. Bending radius: Bending radius refers to the curvature radius of the internal and external bending parts of a metal sheet during the bending process. The size of the bending radius is determined by the thickness and hardness of the material. In general, the bending radius should be greater than twice the thickness of the material to avoid problems such as cracking and deformation.

5. Bending force calculation: When bending sheet metal, the required bending force needs to be calculated. The magnitude of bending force is related to factors such as material strength, bending angle, board width, and board thickness. Through reasonable calculations, it can be ensured that the mechanical properties during the bending process meet the design requirements

6. Bending error control: During the sheet metal bending process, certain bending errors may occur due to the elastic deformation of the material and the limitations of the process. To ensure product quality, it is necessary to control bending errors. Common control methods include adjusting the size of the bending mold, optimizing the bending process, and processing equipment.

7. Compensation and correction: During sheet metal bending, due to the elastic recovery of the material and the limitations of the process, the bent parts may experience certain deformations. To ensure the dimensional and shape accuracy of the product, compensation and correction are required. The methods of compensation and correction include reserving material thickness, adjusting bending angle appropriately, and using specialized correction equipment.

Sheet metal bending, as an important sheet metal processing technology, is widely used in various fields such as electronics, communication, automotive, aerospace, etc. Mastering the basic knowledge of sheet metal bending is of great significance for improving product quality and reducing production costs. Through reasonable material selection, bending process control, and error correction, precise and stable sheet metal products can be produced to meet market demand.