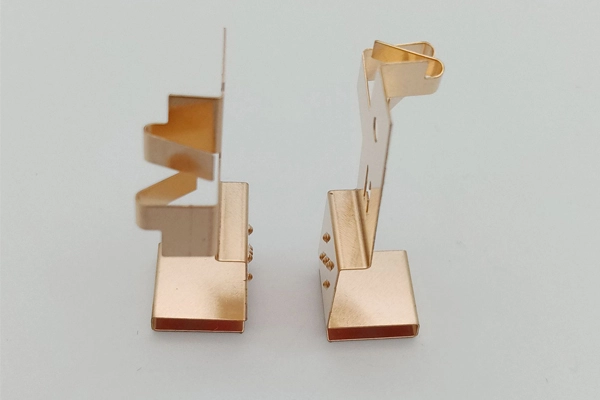

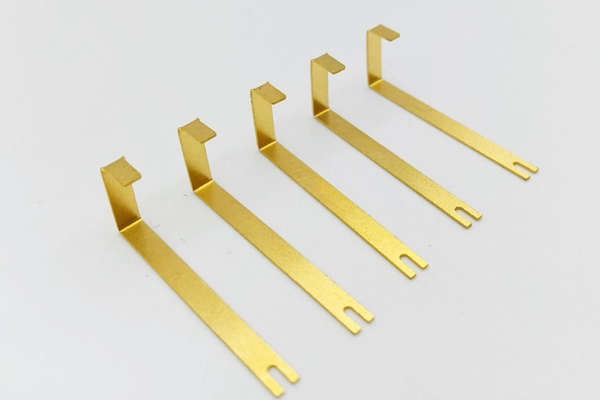

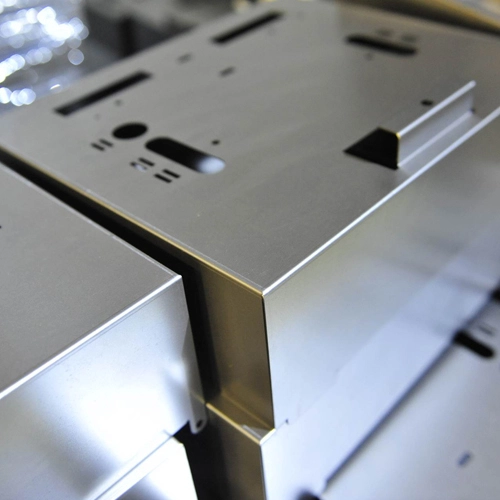

At Yixing Technology, we specialize in copper sheet metal fabrication, offering comprehensive services such as stamping, deep drawing, welding, and laser cutting for various copper materials. Copper alloys, including brass, bronze, and white copper, are processed with precision to leverage their excellent conductivity, thermal conductivity, ductility, and corrosion resistance.

With extensive expertise and advanced facilities, Yixing Technology delivers reliable and cost-effective solutions in copper sheet fabrication, helping clients achieve optimal performance for their applications.

With our professional engineers and advanced equipment, we can help customers to realize their custom copper stamped parts and copper deep drawing parts from prototyping to mass production. We have participated in thousands of different copper custom sheet fabrication projects in design, prototyping, batch production, mass production, quality control and delivery successfully.

As a proficient precision sheet metal fabrication factory, we have manufactured copper stamping parts, copper deep drawing parts and copper welded parts for more than 15 years and they are widely used in automobile industry, power industry, water treatment industry, new energy industry etc. Such as components in generator, bus box, circuit breaker, controller, weir doors, pumps, control valves, pipe joints, wind turbines, solar generators and so on.

Conductivity and Thermal Conductivity: Copper ranks second only to silver in terms of conductivity and thermal conductivity. And the price is much lower than gold and silver.

Corrosion Resistance: Generally speaking, the corrosion resistance of copper sheet fabrication is lower than that of gold, platinum, silver, and titanium, while gold, platinum, and silver are precious metals with very small practical application scales; Compared to metals such as iron, zinc, and magnesium, copper has strong corrosion resistance. Compared with aluminum, copper is more resistant to corrosion from non oxidizing acids, alkalis, and seawater. However, aluminum has stronger corrosion resistance than copper in media such as atmosphere and weak acids.

Easy to Process: Copper has moderate strength (200-360MPa), and its deformation resistance is greater than that of aluminum but much lower than that of steel and titanium. Copper has good plasticity and can withstand large amounts of cold and hot pressure processing, such as rolling, extrusion, forging, precision deep draw, stamping, bending, etc. The deformation degree of rolling and deep drawing can reach over 95% without the need for intermediate annealing and other heat treatments.

Color: Pure copper is a simple and elegant purple (also known as ancient copper color), while copper alloys have various beautiful colors, such as golden yellow (H65 brass), silver white (white copper, zinc white copper), blue (aluminum bronze, tin bronze), etc., which are either gorgeous or dignified, and are very popular among people.

Antibacterial Properties: Copper can inhibit the growth of bacteria and other microorganisms, and 99% of bacteria in water will be completely killed after 5 hours in a copper environment. This is very important for drinking water transmission, food containers, marine engineering, and more.

Solderability: Copper is easy to weld using methods such as soft brazing, hard brazing, and gas shielded arc welding. Phosphorus deoxidized copper with a small amount of phosphorus has better weldability. Due to the good thermal conductivity of copper, copper welding requires high-power and high-energy beam welding facilities, and it is best to perform gas protection. Spot welding is generally not recommended.

Plating Ability: Copper has good plating ability, which can be used for electroplating high melting point metals such as nickel, chromium, etc., as well as for hot plating low melting point metals such as tin, zinc, etc.

Non Magnetic: pure copper is a non-magnetic metal.