1. Strong corrosion resistance: The surface anti-corrosion performance is very high, and can effectively prevent acid, alkali and salt erosion. It is the best variety to prevent the corrosion of building mortar.

2. Satisfactory performance life: The electrophresis aluminum can ensure the life of more than 50 years does not corrode even in harsh environments, decorative use. No aging. No color fading. Do not fall off.

3. The electrophresis aluminum is smooth and delicate to feel, with bright and colorful appearance, which is rich and magnificent. Electrophresis aluminum provides variety of colors to choose from.

4. With Paint film hardness, electrophresis aluminum Can withstand more than 3H aluminum pen hardness painting and engraving.

The substrate is used as anode and placed in electrolytic solution for electrolysis, which artificially forms a layer of protective oxide film on the surface of the substrate, thus forming oxidized aluminum material.

The main characteristics of oxidized aluminum:

1.It has strong abrasion resistance, weather resistance and corrosion resistance.

2.Oxidized Aluminum can form a variety of colors on the surface to meet your requirements maximumly.

3.Strong hardness, suitable for all kinds of construction and industrial materials.

Metal foam material is a new type of engineering material that integrates physical function and structure. It has a variety of excellent physical properties that make it widely used in many fields, such as anechoic, shock absorption, separation engineering, catalytic carrier, shielding and protection. Among them, the foam aluminum made of rare earth aluminum alloy is also considered a promising material for future cars, ships and other transportation tools.

The process is divided into two parts: 1. the development of rare earth aluminum alloy; 2. the preparation of rare earth foam aluminum alloy.

The development of rare earth aluminum alloy can not only improve the strength of the alloy, but also reduce the melting temperature of the alloy, which is conducive to the preparation of strong rare earth foam aluminum alloy. Under a certain alloy viscosity, foaming with a suitable foaming agent uniformly dispersed into the melt is the technical key to the preparation of foam metal. In the rare earth additives for rare earth aluminum alloys, the rare earth content is from 0.1% to 0.7%.

The rare earth foam aluminum alloy is prepared by melt foaming method, using aluminum alloy as the base metal, melting with self-formulated rare earth additives in the molten state, after obtaining the rare earth aluminum alloy melt, adding metal viscosity builder and foaming agent, and carrying out the foaming reaction in the rare earth aluminum alloy foaming pool, and then obtaining the rare earth foam aluminum alloy after molding.

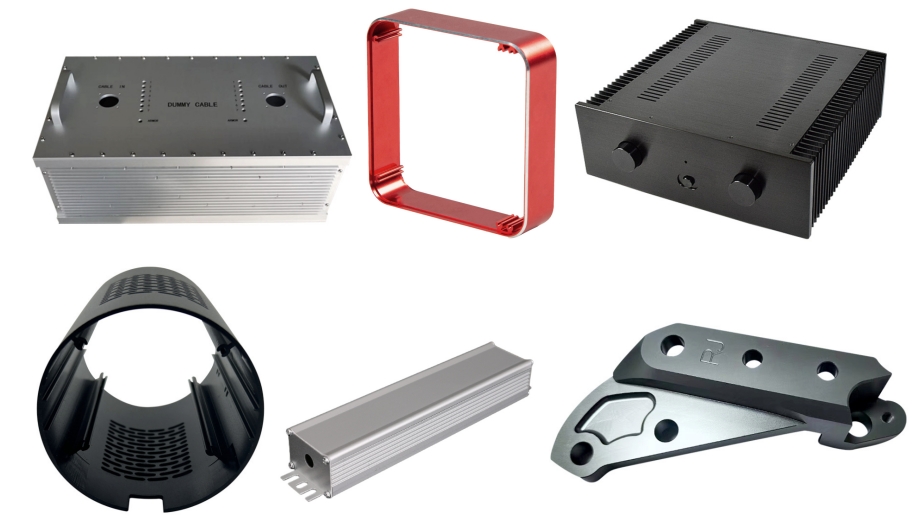

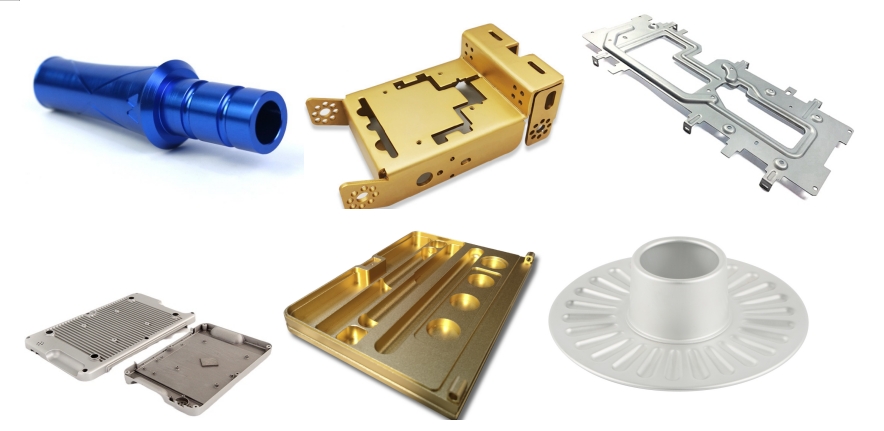

Building products made of aluminum and aluminum alloys. Usually, they are processed into castings, forgings, foils, plates, strips, tubes, rods, profiles, etc., and then made by cold bending, sawing, drilling, assembling, coloring, and so on.

Properties Pure aluminum has low strength and its use is limited. However, by adding a small amount of one or several alloying elements, such as magnesium, silicon, manganese, copper, zinc, iron, chromium, titanium, etc., aluminum alloys with different properties can be obtained. Aluminum alloy and then by cold working and heat treatment, further strengthened and hardened, its tensile strength greatly increased.

Aluminum's standard potential is -1.67 volts, chemical properties are very active, easy to play with the oxygen in the air and the formation of a layer of solid dense oxide film, so in the ordinary atmosphere and clean water, aluminum has good corrosion resistance. However, galvanic corrosion occurs when contacting with steel or other metal materials, and corrosion occurs when contacting with alkaline materials such as concrete, cement mortar, lime, etc. in humid environments, and corrosion occurs when contacting with wood, soil, etc. Therefore, it is necessary to carry out appropriate measures to prevent corrosion. Therefore, appropriate anti-corrosion treatment is required.

Production method Aluminum alloy is divided into two categories, cast aluminum alloy and deformed aluminum alloy, according to different production methods. Aluminum alloys are generally used in construction to be rolled into plates, foils and strips, and extruded into rods, tubes or profiles of various complex shapes. Deformed aluminum alloys are divided into rust-proof aluminum alloys, duraluminum, super duraluminum and special aluminum according to their different properties and uses. Industrial pure aluminum (L1~L1), rust-proof aluminum alloys (LF2, LF21, etc.) and wrought aluminum (LD2) are generally used in construction.

The most important characteristic of aluminum and aluminum alloys is that their weight capacity is about 1/3 of that of steel, while their specific strength (the ratio of the strength limit to the specific gravity) can reach or exceed that of structural steel. Secondly, aluminum and aluminum alloys can be easily processed into various shapes and adapted to a variety of connection processes, thus providing favorable conditions for building structures to adopt the most economical and reasonable sectional forms. Therefore, the use of aluminum alloy can not only greatly reduce the weight of the building, saving materials, but also reduce the transportation of components, installation workload, speed up the construction progress. This is a more significant economic effect for earthquake areas and mountainous and remote areas with inconvenient transportation. Aluminum and aluminum alloys have beautiful color, good corrosion resistance, high reflectivity to light and heat, good acoustic performance, and a variety of different colors can be obtained through chemical and electrochemical methods. So aluminum is widely used in industrial and civil buildings for roofs, walls, doors, windows, skeletons, internal and external decorative panels, ceilings, suspended ceilings, railing handrails, indoor furniture, store containers and templates for construction.

The construction industry is one of the three major markets for aluminum, about 20% of the world's total aluminum production is used in the construction industry, and in some industrially developed countries, the amount of aluminum used in the construction industry has accounted for more than 30% of their total production. Architectural aluminum products are constantly updated, colored aluminum panels, composite aluminum panels, composite door and window frames, aluminum alloy templates and other novel architectural products application is also increasing year by year. China has applied aluminum alloy by using custom aluminum sheet fabrication or other technology in industrial and civil buildings to make roofs, walls, doors and windows, etc., and gradually expanding to internal and external decoration, construction templates, etc., and has achieved good results.