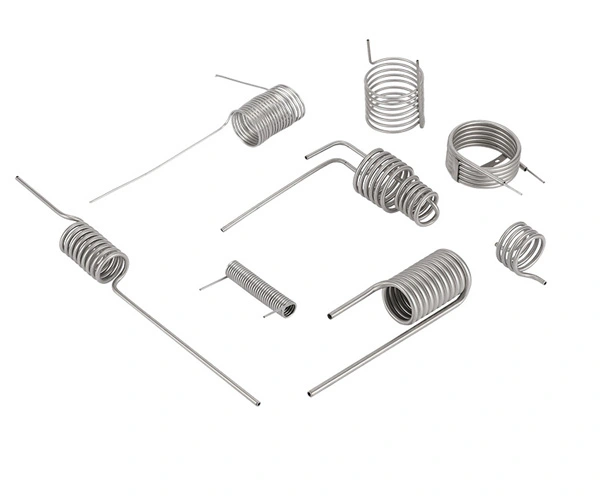

Surface: clean

Customized Size

Tolerance: ±0.1mm

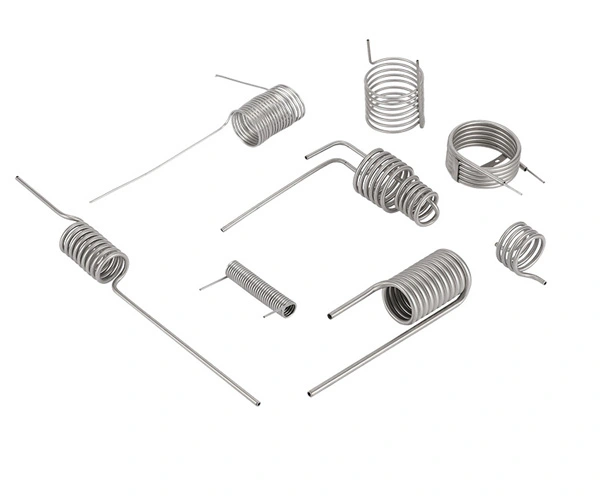

Tube bending and welding, cart handle, pipe bending

The processing process of the coil includes the following steps:

1. Material preparation: Select suitable materials and perform necessary cutting and pre-treatment on the materials.

2. Twist: The preprocessed material is twisted manually or mechanically to form the desired shape. This may involve bending the material into circular, elliptical, or other designed shapes.

3. Stamping: Stamping operations are carried out on part or all of the coil to ensure that its shape and size meet the design requirements.

4. Welding: Use manual or automatic welding techniques to join the two parts of the coil to form a closed circular structure. During the welding process, attention should be paid to controlling the welding time and temperature to avoid defects such as deformation or air leakage.

5. Cleaning and testing: Clean the welded coil to remove residual oil and other pollutants. Then conduct inspections such as appearance, airtightness, and pressure testing to ensure that the product quality meets the design standards.

6. Packaging and transportation: Properly package the tested and qualified coils to protect them from damage and prepare them for good delivery to the next production stage or user's hands. The commonly used packaging methods include wooden box packaging and cardboard box packaging.