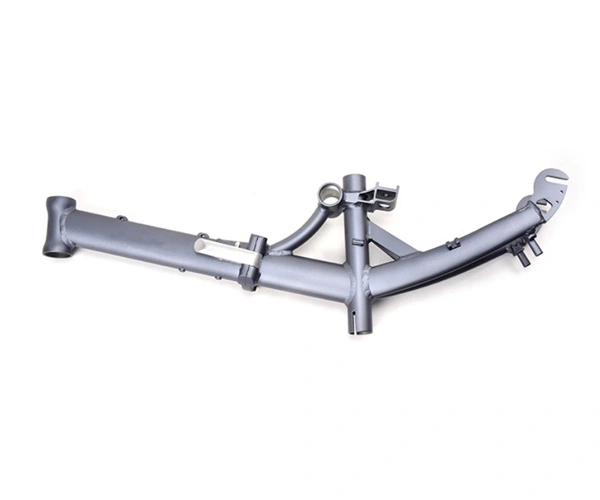

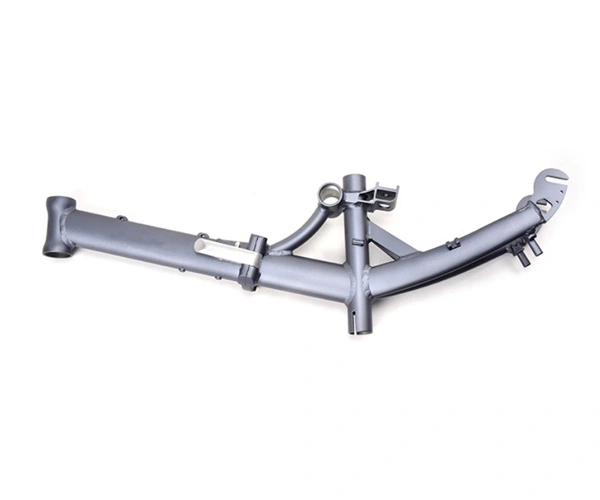

Surface: powder coating, spray painting

Customized Size

Tolerance:±0.2mm

Main Process: tube bending, welding mountain bike frame welding, tube and pipe bending welding

1. Definition of Welding

Welding is a commonly used method of joining two or more metal or non-metallic components together through heating or high pressure. Welding can form a tight connection, and its connection strength can reach or even exceed the strength of the original structure itself, so it has a wide range of applications in various industries and fields.

2. Classification of welding

(1) Classified by material

Welding can be divided into metal welding and non-metal welding. Metal welding includes gas welding, arc welding, argon arc welding, laser welding, etc; Non metallic welding includes plastic welding, rubber welding, glass welding, etc.

(2) Classification by welding method

Welding can be divided into manual welding and automated welding. Manual welding is a welding method that requires high skills from welders and is mainly used for maintenance or small-scale production; Automated welding is a welding method that is completed by machines themselves, which can greatly improve work efficiency and production efficiency.

(3) Classified by welding technology

There are various classification methods for welding technology, including common ones such as arc welding, laser welding, ultrasonic welding, friction welding, etc. Different welding techniques are suitable for different welding application scenarios and can be selected according to needs.

3. Summary

Welding is a widely used metal processing method, which has advantages such as high connection strength and high production efficiency. According to different welding materials, welding methods, and welding techniques, welding is divided into various types and can be selected according to actual needs.