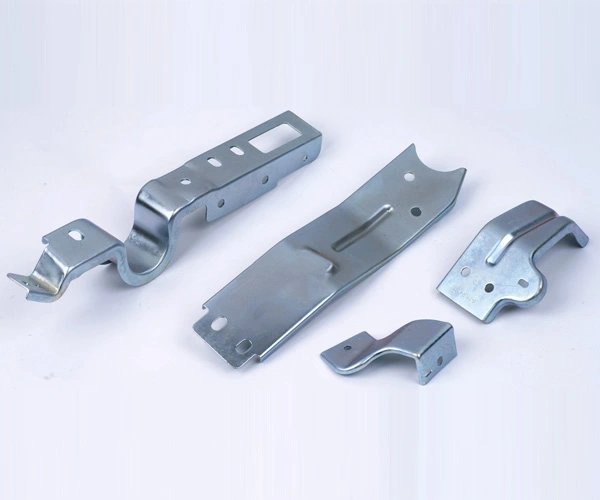

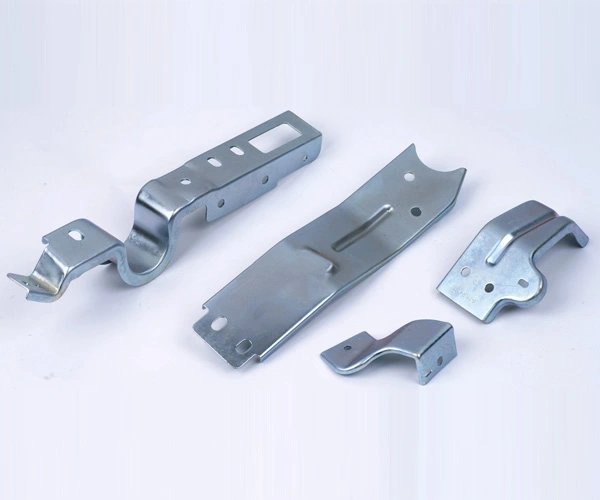

Material: SECC

Surface: Zinc plated/Painting/Powder coating etc

Customized Size

Tolerance: ±0.025mm

progressive stamping in China, stamping electrical parts, press metal construction parts, punching car components, stamping solar support

A. Separation process:

The finished and semi-finished products with a certain shape, size, and cross-sectional quality are obtained by separating the sheet material along a certain contour line under external forces. Separation condition: The stress inside the deformed material exceeds the strength limit σ B.

a. Blanking

Use a punch to cut along a closed curve, with the lower part being the part. Used for manufacturing flat parts of various shapes.

b. Punching

Use a punch to cut along a closed curve, and the lower part is waste material. There are several forms of punching, such as forward punching, side punching, and hanging punching.

c. Trimming

Trim the edges of the formed parts neatly or cut them into a certain shape.

d. Separation

Use a die to cut along an unclosed curve to produce separation.

When forming left and right parts together, the separation process is more commonly used.

B. Forming process:

The billet undergoes plastic deformation without rupture to obtain finished and semi-finished products of a certain shape and size.

Forming condition: yield strength σ S.

a. Stretching

Forming blank sheets into various open hollow parts.

b. Flanging

Form a vertical edge of the sheet or semi-finished product along a certain curve and curvature.

c. Sizing

The forming method used to improve the dimensional accuracy of formed parts or obtain small fillet radii.

d. Flipping hole

Make vertical edges on pre punched or semi-finished plates or un-punched plates.

e. Bending

Bending the sheet metal into various shapes along a straight line can process extremely complex parts.