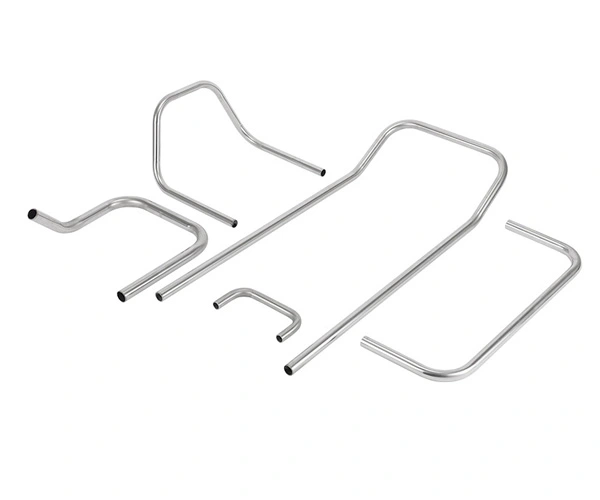

Material: SS304/SS316

Surface: Mirror

Customized Size

Tolerance: ISO 2768-C

cart handle, curved angle handle, U-shaped double bending handle

304 stainless steel round pipe is a hollow circular stainless steel pipe widely used in various building decoration fields such as wall guardrails, staircase handrails, and courtyard doors. The bending technology requires smoothness, precise angle, and no cracking. Today, the editor will introduce the bending technology of 304 stainless steel round pipes.

1. Method of bending circular pipes

(1) Hot bending method: First, based on the outer diameter of the 304 stainless steel circular tube, fix the rollers on the iron plate, fill the tube with sand, plug both ends of the tube with wooden plugs, and heat the bent area with flame before bending.

(2) Cold bending method: It can be formed by rolling multiple times with a bending machine. Before using the bending machine, it is necessary to do a trial run. There must be a gap at the bottom with a plate thickness, and the bending groove must be selected with a groove that is 8 times the plate thickness.

2. Technical difficulties

(1) During processing, the friction between the workpiece and the tool generates high heat, making the tool prone to wear. So the requirements for tool materials are even stricter, requiring wear resistance and high temperature resistance. And it must meet the requirement of sharp blade.

(2) Slow processing speed, high stress during cutting process, and low production efficiency; In addition, due to its high heat generation, sulfur chloride, a good cooling oil, is generally used for better results. The most difficult tasks are drilling deep holes and tapping. Therefore, workers in the processing of 304 stainless steel round pipes are required to have good experience and skills.

3. Precautions

(1) Bend: The general requirement for 304 stainless steel round pipe bend R is that the bend radius (centerline) R is ≥ 1.5~2 times the diameter. If the bend R angle is too small, the bend R angle part will be flat. The R angle of the same stainless steel pipe is generally consistent to meet the consistency of the wheel mold. The straight edge length of the bent pipe must be ≥ 2 times the diameter, otherwise the bent pipe mold cannot be clamped smoothly.

(2) Process holes: 304 stainless steel round pipe welds should consider reserving process holes to better discharge the welding slag generated during welding.

(3) Processing performance: First of all, attention should be paid to the processing performance of 304 stainless steel round pipes. Stainless steel has high plasticity and toughness during cutting, high cutting energy consumption, high cutting temperature, low thermal conductivity of stainless steel, poor heat dissipation, which can easily cause tool temperature rise, enhance the adhesion and weldability of stainless steel, and easily block the accumulation during cutting, ultimately leading to a decrease in the surface smoothness of stainless steel pipes.