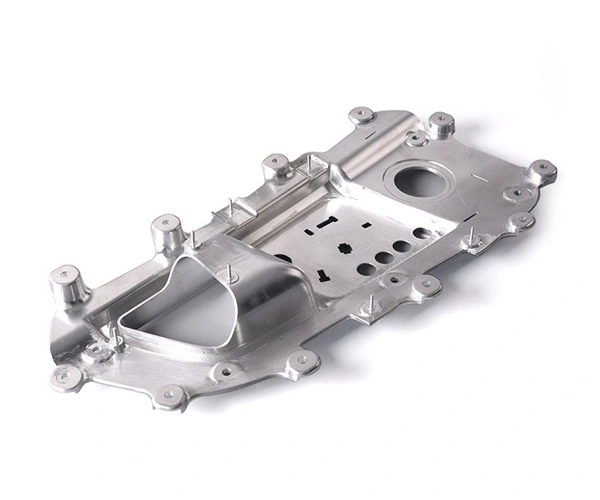

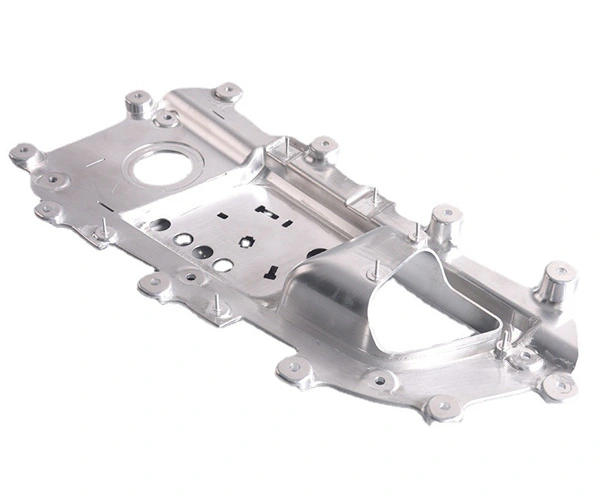

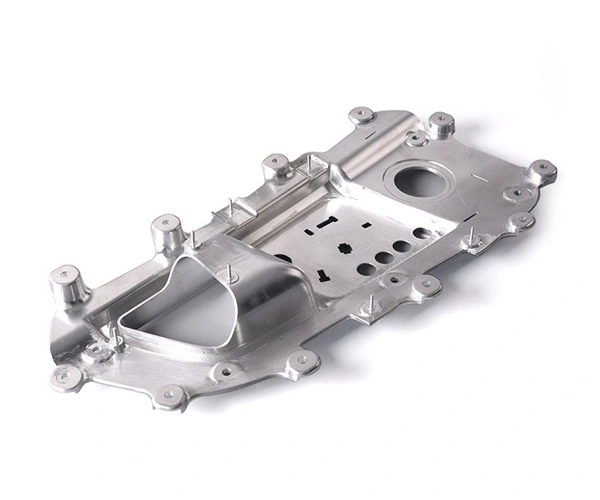

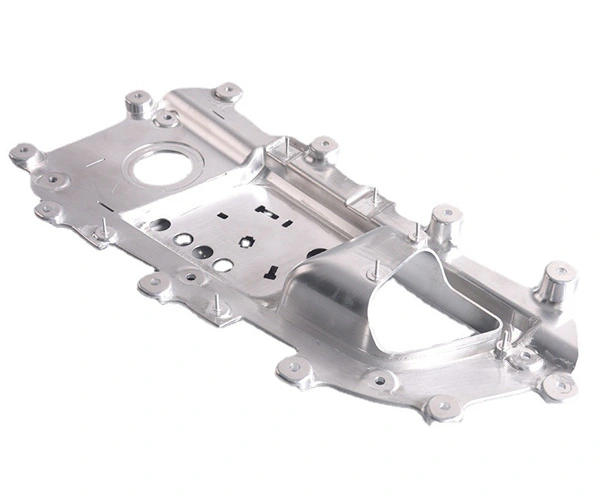

Material: SECC

Surface: Zinc plated/Painting

Customized Size

Tolerance: ±0.025mm

stamping metal car components, custom high quality automotive parts

1. Stamping is a processing method with high production efficiency and low material consumption. Stamping technology is suitable for the production of large batches of parts, facilitating mechanization and automation, and has high production efficiency. At the same time, stamping production not only strives to achieve low waste and zero waste production, but also can fully utilize even if there are leftover edges and corners in certain situations.

2. The operation process is convenient and does not require the operator to have a high level of skill.

3. Stamped parts generally do not require further mechanical processing and have high dimensional accuracy.

4. Stamped parts have good interchangeability. Stamping processing has good stability, and the same batch of stamped parts can be exchanged for use without affecting assembly and product performance.

5. Due to the use of sheet metal as the material for stamped parts, their surface quality is good, providing convenient conditions for subsequent surface treatment processes such as electroplating and painting.

6. Stamping processing can obtain parts with high strength, high stiffness, and light weight.

7. Stamped parts produced in bulk using molds have low costs.

8. Stamping can produce complex shaped parts that are difficult to machine using other metal processing methods.

Stamping process is a metal processing method that is built on the basis of plastic deformation of metal. It uses molds and stamping equipment to apply pressure to the sheet metal, causing plastic deformation or separation of the sheet metal, thereby obtaining parts (stamped parts) with certain shape, size, and performance.