Stainless steel is often classified according to the state of organization: martensitic steel, ferrite steel, austenitic steel, austenitic - ferrite (duplex) stainless steel and precipitation hardening stainless steel. In addition, according to the composition can be divided into: chromium stainless steel, chromium-nickel stainless steel and chromium-manganese-nitrogen stainless steel. There are also specialized stainless steels for pressure vessels.

1. Ferritic Stainless Steel

Ferritic stainless steel contains 15% to 30% chromium. Its corrosion resistance, toughness, and weldability improve with increasing chromium content. It has better chloride stress corrosion resistance compared to other types of stainless steel. The high chromium content, corrosion resistance and oxidation resistance of ferritic stainless steel are relatively good, However, the mechanical properties and process performance is poor, it is used for the acid-resistant structure of the force which not big and for the use of oxidation-resistant steel. This kind of steel can resist the corrosion of the atmosphere, nitric acid and brine solution, and has good high temperature oxidation resistance, small coefficient of thermal expansion, etc., It is used in nitric acid and food factory equipment, which can also make the parts working at high temperature, such as gas turbine parts.

2. Austenitic Stainless Steel

This stainless steel contains more than 18% chromium, also contains about 8% nickel and a small amount of molybdenum, titanium, nitrogen and other elements. Comprehensive performance is good, can be resistant to a variety of media corrosion. This type of stainless steel has good plasticity, toughness, weldability, corrosion resistance, non-magnetic or weakly magnetic, and it’s corrosion resistance in oxidizing and reducing media are better, the austenitic stainless steel is usually used to make acid-resistant equipment, such as corrosion-resistant containers and equipment lining, conveying pipelines, nitric acid-resistant equipment parts, etc., Besides, austenitic stainless steel can also be used as a stainless steel watch jewelry body material.

3. Precipitation Hardening Stainless Steel

The matrix is austenitic or martensitic organization, precipitation hardening stainless steel commonly used grades are 04Cr13Ni8Mo2Al and so on. It can be precipitation hardening (also known as age hardening) treatment to make it hard (strong) stainless steel.

4.Martensitic Stainless Steel

The common grades of martensitic stainless steel are 1Cr13, 3Cr13, etc. Because of the high carbon content, it has high strength, hardness and abrasion resistance, but the corrosion resistance is a little poor, This type of stainless steel is commonly used in the mechanical properties which the requirements is high, but corrosion resistance requirements below general requirements, such as springs, turbine blades, hydraulic valves and so on. This martensitic stainless steel is used after quenching and tempering treatment. Annealing is required after forging and stamping.

5. Stainless Steel Plate And Strip For Pressure Equipment

Stainless steel for pressure vessels, which has clear requirements in classification and designation, size, shape and allowable deviation, technical requirements, test methods, inspection rules, packaging, marking and product quality certificates. Commonly used grades are 06Cr19Ni10, 022Cr17Ni12Mo2 digital code: S30408, S31603 and so on. This type Stainless steel is mainly used in food machinery, pharmaceutical machinery and other sanitary equipment.

Construction Field

Most of the stainless steel is used in the construction industry. The sustainable steel structures can be built quickly at low cost. The various forms and alloys of stainless steel can be designed to meet the requirements of unique projects so that they can be integrated into the infrastructure of all environments. Depending on the conditions in which the structure is located, stainless steel can be alloyed or surface treated differently for protection.

The development of efficient stainless steel production techniques in the late 20th century facilitated the development of railroads around the world and the emergence of high-rise buildings. Many notable historical buildings, such as the Empire State Building, use stainless steel as a primary building material. Examples include stainless steel trim, stainless steel skirting, stainless steel cladding and more.

Stainless steel can also be found in: low and high-rise buildings, educational and hospital buildings, sports stadiums, stations, reinforced concrete, bridge decks, piers and suspension cables, harbors, cladding and roofing, offices, tunnels, security fencing, coastal and flood protection.

Transportation Field

Engineering stainless steels are forged steels designed for flexibility, strength, ductility and corrosion resistance. They are used in general engineering and manufacturing, but mostly in transportation vehicles.

Steel accounts for more than 50% of the weight of an average automobile. Advanced High Strength Steel (AHSS) is used in vehicles. It is a lightweight material that requires less energy to produce and reduces carbon dioxide emissions. Different types of stainless steel are used for bodywork, doors, engines, gearboxes, steering, suspension, wheel axles and interiors. In addition to the automotive market, stainless steel is also found in transportation materials such as: trucks, transmissions, trains, rails, ships, anchor chains, aircraft landing gear, and jet engine components.

Energy Sector

Stainless steel is needed for infrastructure in all areas of the energy sector, including nuclear energy, wind energy, electricity and natural gas. Stainless steel is also used in resource extraction, such as offshore platforms, earthmoving and quarrying equipment, cranes and forklifts. Carbon, micro-alloyed, high-strength stainless steels are used in the production of offshore platforms and pipelines due to the harsh environmental requirements. In addition to this, many other energy projects rely on large quantities of stainless steel: oil and gas wells and platforms, pipelines, power turbine components, electric towers, wind turbines, transmission towers, electromagnets, transformer cores, electromagnetic shielding.

The Field of Packaging

Packaging with stainless steel protects goods from water, air and light and is fully recyclable. This method of storage has existed for over 200 years. Stainless steel allows high-speed filling and lightweight, easy-to-open packaging. Packaging stainless steel is usually made from low carbon cold rolled steel strip with a surface treatment. The stainless steel is tin-plated to prevent corrosion, then coated with a polymer, painted, and printed. Most stainless steel packaging is oriented toward food and beverage containers, followed by general lines, aerosols, and caps (e.g., bottle caps).

Appliances and Industry

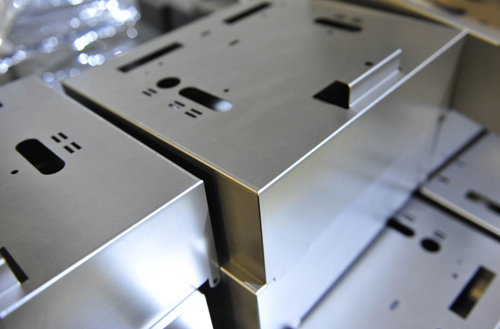

About 75% of the weight of a typical household appliance comes from stainless steel. Stainless steel is found in equipment such as refrigerators, washing machines, ovens, microwaves, sinks, cutlery and more. Stainless steel is also involved in many industrial stainless steel sheet fabrication products such as stainless steel products, agricultural vehicles and machinery, tanks, tools, structures, sidewalks and protective equipment. Many 304 stainless steel manufacturers have also developed many 304 stainless steel trim designs, models and patterns for consumers to choose from.

Yixing Technology is a leading sheet metal fabrication factory specializing in custom metal manufacturing over 20 years, with over 5000 square meters of facilities, serving more than 1000 customers around the world. We provide professional custom sheet metal services for all your needs.