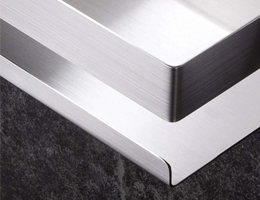

Yixing Tech specializes in the production of stainless steel products. With advanced equipment and technology, we are capable of handling a wide range of fabrication needs, from precision small components like shafts, gears, terminals, springs, pins, contact chips to large structural parts like enclosures, sinks, handles, frames, chassis, railing etc. We boasts of high precision, durability, and consistency for our stainless steel fabricated products.

Wide Range Capabilities: Our equipment capabilities cover various complex processes, including cutting, forming, welding, CNC machining and surface treatment, ensuring the fulfillment of diverse customer requirements.

ISO9001 Strict Quality Control: Strictly adhere to international quality standards, with every step from raw material procurement to finished product delivery undergoing rigorous inspection.

Professional Technical Team: Our engineers have more than 30 years experience in custom stainless steel fabrication who can understand customers English drawings and their specific requirement.

Friendly for Small or Large Projects: No matter you need 10pcs, 1000pcs or 1million pieces, we offer non-biding cost analysis. Support customers with prototypes to verify the design and quality.

Custom stainless steel fabrication involves designing, cutting, shaping, and assembling stainless steel to create products tailored to specific customer needs —meeting their function requirement, test requirement, usage environment requirement. Custom stainless steel fabrication is ideal for producing industrial parts, architectural structures, kitchen equipment, and medical devices. Stainless steel offers durability, corrosion resistance, and a sleek finish, making it suitable for demanding applications. Its versatility allows for complex designs, while its non-porous surface ensures hygiene. Our custom metal fabrication service has delivered tailored, high-quality solutions for diverse industries.

In Yixing Technology, we use stainless steel material to do sheet metal bending, laser cutting, stamping, deep drawing, CNC machining, metal spinning and welding. Our factory production space is more than 5000 ㎡, which is equipped with flat laser cutting machine, 3D laser cutting machine, CNC turning and milling machines,precision CNC punching machines, hydraulic press, robot welding machines etc to make various parts like stainless steel brackets, stainless steel shells, stainless steel cabinets, stainless steel containers, stainless steel guardrails and other stainless steel products.

|  |  |

| Stainless Steel Machining | ||

|  |  |

|  |

• Excellent corrosion resistance

• Excellent mechanical properties

• High temperature resistance

• Excellent welding performance

• Good wear resistance

• High strength

We can provide kinds of surface treatment on our stainless steel parts to enhance durability, aesthetics, and functionality. We do mirror-polishing or electro-polishing for a smooth, reflective finish, brushing for a matte appearance, and passivation to improve corrosion resistance. Sandblasting or bead blasting can be applied to create a textured surface or for powder coating purpose. We can also do electroplating to add additional protective layers for special working environment. These treatments ensure the final product meets specific industrial or decorative requirements. If you cannot find the surface treatment listed below, please contact with us. We have strong supplier chain to reach the customization requirement.

Passivation Electropolishing

Chemical coloring PVD Coating

Mirror polishing Wire drawing/Brushing

Electroplating Powder coating

Sandblasting Laser engraving

Stainless steel fabrication products we make: Gears, shafts, valves, brackets etc.

Stainless steel fabrication products we make: Tanks, conveyors, mixers, processing equipment,etc.

Stainless steel fabrication products we make: Surgical instruments, equipment housings, sterilization trays etc.

Stainless steel fabrication products we make: Structural beams, facades, railings, decorative elements etc.

Stainless steel fabrication products we make: Exhaust systems, engine parts, structural frames etc.

Stainless steel fabrication products we make: Pipelines, heat exchangers, turbine parts etc.

Stainless steel fabrication products we make: Propellers, hull fittings, offshore platform structures etc.

Stainless steel fabrication products we make: Enclosures, connectors, mounting hardware etc.

Stainless steel fabrication products we make: Reactors, storage tanks, piping systems etc.

Stainless steel fabrication products we make: Kitchen appliances, cutlery, furniture etc.

Competitive Pricing

We provide cost-effective solutions without sacrificing quality. Win-win is our strategy for long term development.

Fast Turnaround

Our efficient production process and simplified workflow enable us to deliver projects on time, even for urgent needs.

Comprehensive Services

From prototype production to mass production, we provide end-to-end manufacturing services, offering customers a one-stop service experience and reducing supplier management costs.

Customer-Centric Approach

We prioritize customer satisfaction, responding to instant messages immediately, emails within 24 hours, clear communication, and reliable after-sales service.

Replacing nickel with manganese,200 series have poor corrosion resistance and are widely used as a low-cost substitute for the 300 series in China.

It has good ductility and is used for forming products, can also be quickly hardened through mechanical processing, and has good weldability. Wear resistance and fatigue strength are better than 304 stainless steel.

The corrosion resistance is the same as 304, but the strength is better due to the relatively high carbon content.

By adding a small amount of sulfur and phosphorus, it is easier to be machined than 304.

Most widely used. Namely 18/8 stainless steel, products such as corrosion-resistant containers, tableware, medical equipment, etc. The standard composition is 18% chromium plus 8% nickel.

It is similar to SS304 but the low carbon content of 304L gives it better welding performance and resistance to intergranular corrosion.

With the same characteristics as 304, it is a nitrogen-containing stainless steel, and adding nitrogen is to improve the strength of the steel.

Compared to 304, it has better temperature resistance, with a temperature resistance of up to 980 ℃.

With a high amount of chromium and nickel, it has excellent heat resistance and oxidation resistance. Products such as heat exchangers, boiler components, and jet engines.

Excellent high-temperature and oxidation resistance, with a maximum operating temperature of 1200 ℃.

As the second widely used steel grade after 304, 316 is mainly used in the food industry, watch accessories, pharmaceutical industry, and surgical equipment. Adding molybdenum element gives it a special corrosion-resistant structure. Due to its better resistance to chloride corrosion(compared to 304), it is also used as "marine steel". SS316 is commonly used in nuclear fuel recovery devices. 18/10 grade stainless steel is usually also suitable for this application level.

Low carbon makes it more corrosion-resistant and easy to be heat treated. Products such as chemical processing equipment, nuclear power generators, and refrigerant storage tanks.

In addition to reducing the risk of material weld corrosion due to the addition of titanium elements, other properties are similar to 304.

Adding stabilizing element niobium,it is suitable for welding aviation equipment parts and chemical equipment.

Good heat resistance and weak corrosion resistance. 11% Cr and 8% Ni.

Cheap model (British and American), usually used for automotive exhaust pipes, belongs to ferritic stainless steel (chromium steel).

Martensitic (high-strength chromium steel), with good wear resistance but poor corrosion resistance.

The addition of sulfur improved the processing performance of the material.

It is ferritic stainless steel and used for decoration, such as in automotive accessories. Good formability, but poor temperature resistance and corrosion resistance.

High strength cutting tool steel, slightly higher in carbon content, can achieve higher yield strength after appropriate heat treatment, and its hardness can reach 58HRC, making it one of the hardest stainless steels. The most common application example is the razor blade. There are three commonly used models: 440A, 440B, 440C, and also 440F (easy to process type).