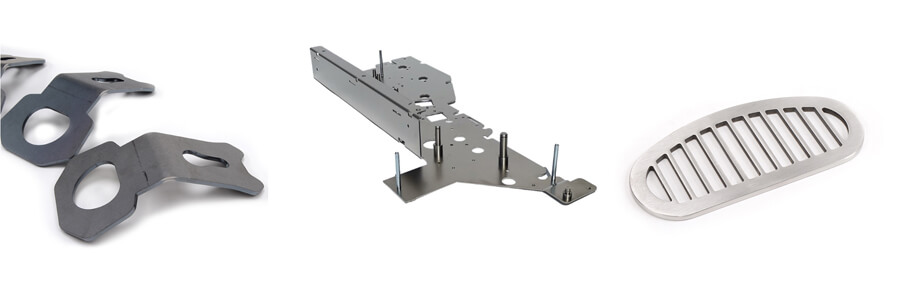

Yixing Technology offers on demand cost-effective laser cutting service no matter you need rapid prototypes, small batch run or big volume production. For over 15 years, we have been focusing on metal laser cutting including steel, aluminum, stainless steel, copper, brass etc. We are also equipped with 3D laser machines to do tube laser cutting for different applications.

We use CO2, fiber, neodymium (Nd), and Nd:YAG laser cutting systems, enabling highly accurate cutting, drilling, and engraving for a wide range of applications.

We are equipped with both 2D and 3D laser cutting machines to laser cut not only flat 2D shapes, but also tubes, pipes and profiles and other 3D products with complex surfaces.

We do rigorous testing and inspection to ensure every part meets design and performance standards.

We do high precision laser cutting with tolerance ranges from 0.005inch to 0.01inch depending on the material and thickness.

Yixing excels in metal laser cutting, leveraging advanced technology and expertise to deliver high-quality, precision laser cut metal components.

Stainless Steel Laser Cutting: For applications requiring corrosion resistance and durability.

Steel Laser Cutting: Commonly used in structural and industrial components.

Aluminum Laser Cutting: Lightweight and ideal for aerospace and automotive industries.

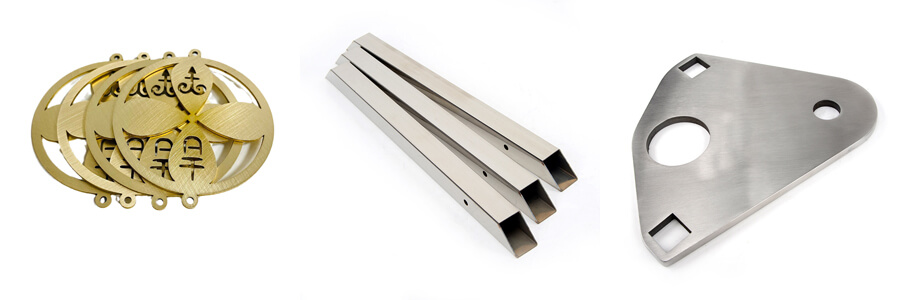

Copper and Brass Laser Cutting: Used in electrical and decorative applications.

Titanium Laser Cutting: For high-strength, lightweight applications in aerospace and medical fields.

| Material | Grade |

| Aluminium | 2024,5052,5754,6061,6063,1060 et |

| Steel | 1008,1018,4140,A36,SPCC,HRS,SAPH440 etc |

| Stainless Steel | 201,301,304,316,17-4 PH,410,430,etc |

| Cold or Hot Dip Galvanized Steel | DC01+Z100,S220GD+Z100,DX51D+Z100,DC01+Z275, S220GD+Z275,DX51D+Z275 etc |

| INCALUME Steel | DC01+AZ150 |

| Spring Steel | 1075 Spring Steel,annealed 1075 Spring Steel,Blue Tempered 1095 Spring Steel,annealed 1095 Spring Steel,blue tempered |

| Brass | Brass 260 Brass 353 H02 Brass 464 H01 |

| Copper | Copper 101,H00 to H01 Copper 110,Annealed Copper 110,H01 Copper 110,H02 |

| Bronze | Bronze 220 H02 Bronze 510 H08(spring) Bearing Bronze 932 M07 Titanium(Grade 2) Titanium 6Al-4V(Grade 5) |

After laser cutting, surface treatment is often necessary to improve the appearance, functionality, and durability of the laser cut parts. At Yixing Tech, we offer a variety of surface treatment options to meet the specific needs of our clients. Here are the most common surface treatment options available:

*Deburing

*Media Tumbling

*Zinc coating

*Plating

Contact us to learn more about how we can optimize your laser cut parts with the right surface treatment!

Yixing Technology has elevated its sheet metal manufacturing capabilities by integrating tube, pipe and profile’s 3D laser cutting services. 3D laser cutting enables precise, efficient, and versatile cutting of complex geometries, tubular materials, and three-dimensional components, catering to a wide range of industries.

Exhaust Systems: Precision cutting of exhaust pipes and components using tube laser cutting.

Chassis and Frames: Cutting and shaping tubular structures for vehicle frames with 3D laser cutting.

Metal Furniture: Cutting and shaping tubes for chairs, tables, and shelving units.

Steel Structures: Cutting tubes and profiles for beams, columns, and trusses with 3D laser cutting machines.

Handrails and Balustrades: Precision cutting of tubes for staircases and balconies with 3D laser cutting.

Hospital Beds and Carts: Cutting tubular frames for medical furniture.

Solar Panel Frames: Precision cutting of aluminum profiles for solar panel mounting systems.

Hydraulic and Pneumatic Systems: Precision laser cutting tubes for fluid and air transport systems.

Conveyor Systems: Precision laser cutting profiles and 3D components for conveyor belts and frames.

Laser cutting offers numerous advantages over traditional cutting methods like mechanical cutting or machining, making it a preferred choice for many industries. Here are the key benefits of laser cutting:

| High Precision and Accuracy | Clean and Smooth Edges |

| Versatility in Material | Low Cost |

| Non-Contact Process | Speed and Efficiency |

| Minimal Material Waste | Automation and Repeatability |

| Flexibility in Design | Reduced Heat-Affected Zone (HAZ) |

Laser cutting is an efficient and economical cutting process. It is the use of a high density laser beam to irradiate a workpiece, causing the irradiated material to vaporize and melt, while using high-speed airflow to blow away the material, in order to cut the workpiece out. It leaves edges with high-quality surface finish. Industrial laser cutting machines are generally used to cut flat materials as well as structural and pipeline materials like tubes, pipes and profiles. Laser cutting is a mainstream metal cutting method known for its accuracy, efficiency, and versatility.

Laser cutting, waterjet cutting, and plasma cutting are three distinct methods used in material cutting, each with unique strengths and limitations. Yixing, with its capabilities in laser cutting, waterjet cutting, and plasma cutting, can leverage the strengths of each technology to serve a wide range of industries and applications.

How it Works

Laser Cutting:Uses a high-powered laser beam to melt, burn, or vaporize material.

Often assisted by a gas jet to blow away molten material and create a clean cut.

Waterjet Cutting: Uses a high-pressure stream of water, often mixed with an abrasive substance, to cut through material.

Pure waterjet cutting is used for softer materials, while abrasive waterjet cutting is used for harder materials.

Plasma Cutting: Uses a high-velocity jet of ionized gas (plasma) to melt and blow away material.

The plasma arc is created by passing gas (e.g., air, nitrogen, argon) through an electrical arc.

Materials

Laser Cutting: Best for metals (steel, stainless steel, aluminum), plastics, wood, and glass.

Not suitable for highly reflective materials (e.g., copper, brass) or materials with high thermal conductivity.

Waterjet Cutting: Can cut almost any material, including metals, stone, glass, ceramics, composites, and plastics.

Ideal for heat-sensitive materials.

Plasma Cutting: Primarily used for electrically conductive metals (steel, stainless steel, aluminum, copper, brass).

Cannot cut non-conductive materials like wood, plastic, or glass.

Thickness Range

Laser Cutting:Thin to medium thickness (up to 20-25 mm for metals, depending on laser power).

Struggles with very thick materials.

Waterjet Cutting: Can cut very thick materials (up to 200 mm or more).

Consistent performance across thicknesses.

Plasma Cutting: Best for medium to thick materials (up to 50 mm or more).

Less efficient for very thin materials (under 3 mm).

The general tolerance for metal laser cutting typically ranges from ±0.1 mm to ±0.5 mm, depending on material thickness, material property, laser cutting machines, cutting parameter, part geometry and application requirements. By understanding these affecting factors and optimizing laser cutting processes, Yixing can deliver high-quality laser cut parts that meet the needs of various industries, from high-precision electronics to heavy-duty construction.

| Material Thickness | Tolerance Range |

| 0.5 mm - 3 mm | ±0.1 mm to ±0.2 mm |

| 3 mm - 6 mm | ±0.2 mm to ±0.3 mm |

| 6 mm - 10 mm | ±0.3 mm to ±0.4 mm |

| 10 mm - 20 mm | ±0.4 mm to ±0.5 mm |

As a metal fabrication shop, Yixing Technology is known for its advanced manufacturing capabilities and we have leveraged our laser cutting services across various industries and applications. For automotive industry, we use laser cutting to make custom metal parts like body panels, exhaust systems, and interior components. For architectural industry, we use laser cutting to produce intricate decorative panels, screens, and facades. For medical industry, laser cutting can be used to make medical devices, such as wheelchairs, patient lifters, stents, catheters, and diagnostic equipment. Almost every metal product in our life can use laser cutting as the first fabrication step plus secondary machinery process which can all be done in our factory.

*Electronics and Semiconductor Industry

*Consumer Goods

*Architecture and Construction

*Renewable Energy

*Art and Design

*Tooling and Molds

Advanced Equipment: In Yixing Technology, we will use state of the art laser cutting equipment like 3D laser cutting machine 1500W and flat laser cutting machine 2000W according to the material type, material thickness and design shape and also other external suppliers resource to fully meet customers' demands.

Hundreds of Material to Cut: We provide accurate and fast sheet metal fabrication services such as custom laser cut services for all industries like automobile, agriculture, solar industry etc. There are hundreds of materials we can laser cut and we do not set minimum order QTY so as to relieve customers’ financial pressures. We are friendly to new start project with small quantities.

Strong Engineer Support: We have professionally trained engineer who can fully control the beam intensity, thermal output, and duration during the laser cutting process. Therefore, our laser cutting process is highly reliable and helps to significantly avoid errors and reduce material waste.

We offer different thickness specifications for different laser cutting materials. The laser cutting equipment parameters will decide what thickness we can cut.

For aluminum laser cutting, the thickest flat sheet we can laser cut is around 10mm.

For stainless steel laser cutting, the thickest flat sheet we can laser cut is around 14mm.

For carbon steel laser cutting, the thickest flat sheet we can laser cut is around 20mm.

Laser cutting is one of the most efficient cutting method that can cut steel materials very fast. This ensures that various cutting projects will be completed very quickly while at the same time save material costs. With precise laser cutting machines in Shanghai Yixing Technology, we can provide faster lead times and reasonable pricing for customers.

For aluminum laser cutting, our cutting speed is around 0.3~0.45m/min.

For stainless steel laser cutting, our cutting speed is around 0.4~0.5m/min.

For carbon steel laser cutting, our cutting speed is around 0.3~0.5m/min.

Our laser cutting service can cut material with a precision of +/- 0.002 inches and a positional accuracy of +/- 0.004 inches. This high precision makes laser cutting an ideal choice for industries that require complex and detailed cutting. For example, precision parts of serrated teeth used in the manufacturing and even production of medical devices.

The accuracy of laser cutting machines is mainly affected by the following factors:

1. Laser beam quality

The better the quality of the laser beam, the smaller the focused spot, and the higher the cutting quality and accuracy.

2. Optical system

High precision and high-quality optical systems can significantly improve the accuracy of laser cutting machines. During the operation of the laser cutting machine, the optical system guides the laser beam very close to the workpiece, ensuring the accuracy and stability of the laser beam, thereby achieving high-precision processing.

3. Machine accuracy

Machine accuracy is also one of the key factors affecting the accuracy of laser cutting machines. The laser cutting machine needs to have a high-precision positioning system, including the workbench, guide rail, servo motor, sensor, and other parts that must ensure accuracy in order to ensure the processing accuracy of the laser cutting machine.

4. Cutting parameters

Different materials and thicknesses require different cutting parameters, such as laser power, spot diameter, gas flow rate, cutting speed, etc. Adjusting these parameters can effectively affect the accuracy of cutting.