We excel in both 2D and 3D laser cutting, delivering precision and versatility for all your sheet metal fabrication needs. Our advanced 2D laser cutting ensures clean, intricate cuts for flat sheet metal, while our 3D laser cutting handles complex geometries with unmatched accuracy. Ideal for thin metal sheets and intricate designs, we provide high-quality results for diverse industrial applications. Besides laser cutting, we also do plasma cutting, shearing, waterjet cutting etc.

Yixing Tech specializes in precision CNC sheet metal bending. We handle a variety of materials and thicknesses, delivering complex shapes with tight tolerances. We do V bend, U Bend, Z bend, Hemming bend, curved bend, box bend and complex multi-section bend. Trust Yixing Tech for efficient and accurate sheet metal bending solutions.

At Yixing Tech, we excel in comprehensive tube and pipe processing, offering a wide range of services including cutting, bending, flaring, swagging, and end forming. Our bending capabilities are highly versatile, encompassing both hot bending (using heat for complex shapes) and cold bending (at room temperature for simpler shapes). We utilize advanced techniques such as press bending, rotary draw bending, compression bending, and roll bending etc to achieve precise and customized configurations.

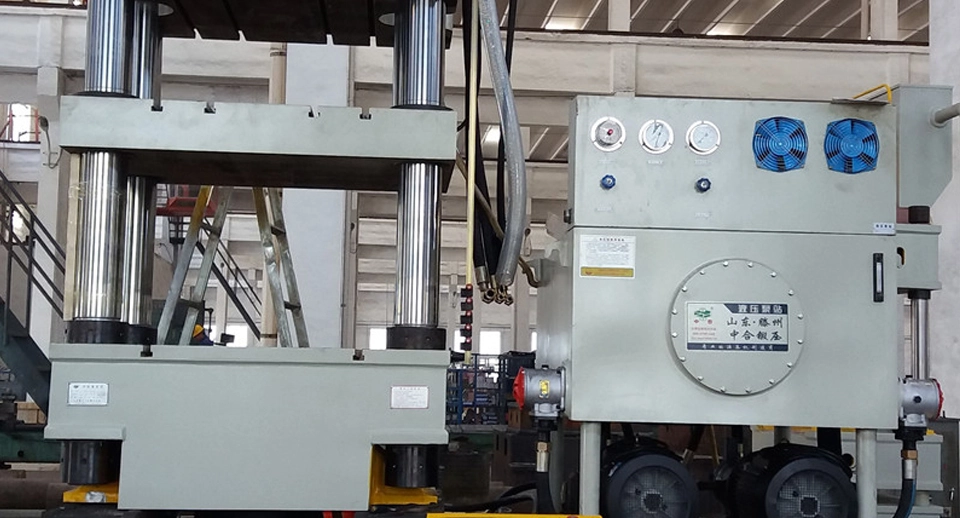

Stamping is a sheet metal forming process in which external forces are applied to sheets, strips, pipes, and profiles by a press and mold, causing plastic deformation or separation, in order to obtain the desired shape and size of the workpiece (stamped part). At Yixing Tech, we specialize in advanced stamping techniques, leveraging state-of-the-art equipment and expert craftsmanship to produce high-quality, custom stamped components.

Deep drawing is a sheet metal manufacturing process used to create parts with deeper depths than those achievable through metal stamping. Specifically, when the depth of the produced part is equal to or greater than its radius, the process is referred to as deep drawing. Yixing Tech specializes in advanced deep drawing techniques, ensuring high precision and quality for complex, deep-drawn components tailored to meet diverse industrial needs.

Progressive die stamping is an important mass production process for producing small but complex metal parts. A metal strip is fed into multiple mold stations, each of which generates one or more features that gradually form the final, fully formed product. Our expertise ensures cost-effective, reliable, and scalable solutions for your sheet metal production needs.

A stamping die is a specialized tool used in cold stamping processes to shape materials (metal or non-metal) into precise parts or semi-finished products. This essential tool/die often referred to as a cold stamping die, plays a critical role in manufacturing by enabling high-precision and high-efficiency production. Yixing Tech specializes in designing and manufacturing advanced stamping dies, combining cutting-edge technology with expert craftsmanship to ensures superior quality and reliability for your production processes.

The process of forming a permanent connection between two or more materials (of the same or different) by heating, applying pressure, or combining the two to achieve atomic bonding is called welding .At Yixing Tech, we specialize in advanced welding solutions, leveraging state-of-the-art technology and expertise to deliver high-quality, durable, and reliable welding results for a wide range of applications.

Unlike progressive die stamping, compound stamping tools perform multiple cutting, stamping, and bending in one stroke, rather than multiple strokes. This is cost-effective for medium batch production operations. Yixing Tech specializes in compound die stamping, offering advanced tooling design and manufacturing capabilities to produce high-quality, precision-engineered parts tailored to your specific requirements.

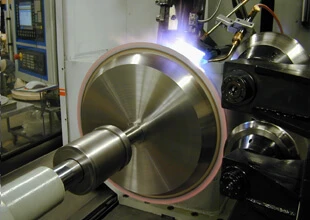

CNC machining is a manufacturing process that uses computer-controlled machine tools to cut, punch, drill, mill, turn, grind, etc. It is a high-precision, high-efficiency, and highly automated processing method. At Yixing Tech, we specialize in advanced CNC machining, leveraging state-of-the-art technology and expert engineering to deliver superior results for a wide range of industries.

Metal spinning is a processing method that forms an axisymmetric rotating body shape. This process uses single-sided cutting tools for processing, also known as "aerial rotation". Whether you need cylindrical, conical, or hemispherical parts, our team ensures exceptional precision, durability, and cost-effectiveness for a wide range of industrial applications.

With extensive expertise in custom sheet metal fabrication and CNC machining, combined with professional technical support and a proven track record of successfully delivering over 20,000 projects, we have earned the trust of more than 3,500 buyers worldwide. If you are seeking reliable sheet metal and CNC machining services in China—whether for laser cutting, stamping, deep drawing, welding, or other processes—simply share your detailed drawings and order quantity with us. Our dedicated, English-speaking team is ready to assist you and will respond to your project inquiries within 24 hours, ensuring a seamless and efficient experience from start to finish. Choose us for precision, quality, and exceptional service tailored to your needs.

Competitive Price: As a mid-sized metal fabrication shop, we keep management costs low and provide detailed cost analysis for accurate, affordable quotes.

Expert Project Management: Our skilled engineers ensure seamless communication and updates, guiding your project from DFM (Design for Manufacturing) to shipment.

In-house Tooling and Secondary Processing: We produce complex and high-precision custom metal parts, and build stamping tools internally to achieve faster turnover and excellent control over design and quality.

Rapid Turnaround Times: With extensive in-house capabilities for sheet metal fabrication and CNC machining and a robust supply chain, we deliver large-scale production quickly and efficiently.

High-Quality Standards: We adhere to strict quality control measures to ensure that your sheet metal and CNC machines parts are produced to the highest quality standards.

By choosing us, you benefit from a combination of affordability, expertise, speed, and uncompromising quality, making us your ideal partner for sheet metal fabrication and CNC machining needs.

Cutting:

Laser Cutting: Uses a high-powered laser to cut precise shapes.

Plasma Cutting: Employs a plasma torch for cutting thicker materials.

Waterjet Cutting: Utilizes a high-pressure water stream mixed with abrasives to cut materials without heat.

Shearing: Cuts straight lines on sheet metal using a shear machine.

Bending:

Achieved using press brakes or folding machines to create angles, channels, or other shapes.

Common bending methods include V-bending, U-bending, and air bending.

Forming:

Stamping: Uses dies to shape or cut metal sheets.

Deep Drawing: Forms metal into hollow shapes like cups or enclosures.

Rolling: Curves metal sheets into cylindrical or conical shapes.

Joining:

Welding: Fuses metal pieces together using heat.

Riveting: Joins parts using mechanical fasteners.

Adhesives: Bonds materials using specialized glues.

Cost-effective: Compared with other fabrication methods, sheet metal fabrication usually requires relatively less equipment, and the fabrication process is simple, which can reduce production costs.

High Accuracy: The application of laser cutting, CNC punching, CNC machining and other equipment has greatly improved the metal fabrication accuracy and can meet the standards of high-precision metal parts.

High Production Efficiency: Sheet metal fabrication can usually achieve large-scale production with high speed. Easy to reach automation and robot configuration.

Flexible Material Selection:custom metal fabrication can work with cold rolled plate, hot rolled plate, galvanized plate, stainless steel, aluminum plate, etc which can meet specific demands for various industries.

Sheet metal fabrication is a manufacturing process that involves shaping and manipulating thin metal sheets (typically less than 6 mm thick) into desired parts or products. This process includes a variety of techniques such as cutting, bending, forming, and assembling to create functional or decorative components. Sheet metal fabrication is widely used across industries due to its versatility, precision, and cost-effectiveness.